—

MOTOR GUIDE | JULY 2019

Low voltage motors Motor guide

2 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

—

We provide motors and generators, services andexpertise to save energy andimprove customers’ processesover the total lifecycle or ourproducts, and beyond.

Motor guide – basic technical informationabout low voltage standard motors

© Copyright 2019 ABB. All rights reserved. Specifications subject to change without notice.

ISBN 952-91-0728-5Fourth edition 2019

—

Table of contents

006 1. Introduction 007 1.1 About ABB

007 1.1.1. Electrification Products007 1.1.2. Robotics and Motion007 1.1.3. Industrial Automation008 1.1.4. Power Grids

008 1.2 IEC low voltage motor ranges008 1.2.1 Standard induction motors

008 1.2.2 Motors for explosive atmospheres009 1.2.3 Frequency-controlled motors

009 1.2.4 Motors for industries and specific applications

010 2. International motor efficiency011 2.1 Standards and regulations011 2.1.1 Minimum energy performance standards012 2.1.2 IEC 60034-30-1:2014

013 2.1.3 ABB and efficiency standards015 2.2 Life cycle approach and energy appraisal015 2.2.1 Energy appraisal

016 2.3 Environmental management within ABB016 2.3.1 ISO 14001

016 2.3.2 Hazardous substances 016 2.3.3 Materials selection

017 2.3.4 EU Directive 2012/19/EU (WEEE)

018 3. Standards 019 3.1 Definitions

020 3.2 Standards tables

020 3.2.1 The main standards for low voltage motors021 3.2.2 The main EU directives for motors021 3.2.3 Efficiency determination for motors outside Europe022 3.3 Direction of rotation

023 3.4 Cooling

024 3.5 Degrees of protection: IP code/IK code025 3.6 Standard voltage ranges026 3.7 Voltage and frequency026 3.8 Tolerance

027 3.9 Mounting arrangements028 3.10 Dimensions

030 3.11 Output power and frame size ratio

4 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

032 4. Electrical design – induction motors033 4.1 The induction motor034 4.2 Insulation 035 4.3 Thermistors

035 4.4 Ambient temperatures and high altitudes036 4.5 Starting methods

036 4.5.1 Direct-on-line (DOL) starting036 4.5.2 Star-delta starting

037 4.5.3 Soft starters

038 4.5.4 Starting with a variable speed drive039 4.6 Starting limitations046 4.7 Duty types 050 4.8 Uprating

051 4.9 Efficiency and types of losses052 4.10 Power factor

055 4.11 Air flow and air speed056 4.12 Connection diagram

058 5. Mechanical design059 5.1 Motor construction060 5.2 Frame constructions061 5.3 Terminal boxes 063 5.4 Bearings

064 5.5 Drain holes and humidity065 5.6 External radial and axial forces of the motor065 5.7 Balancing 066 5.8 Vibration

067 5.9 Surface treatment

068 6. Noise

069 6.1 Sound pressure level and sound power level070 6.2 Weighting filters 071 6.3 Octave bands

072 6.4 Additional sound sources073 6.5 Noise components of a motor075 6.6 Sound pressure levels

5

076 7. Installation and maintenance077 7.1 Delivery acceptance077 7.2 Insulation resistance check078 7.3 Torque on terminals078 7.4 Operation 079 7.5 Handling 080 7.6 Foundations

081 7.7 Coupling alignment082 7.7.1 Mounting pulleys and coupling halves083 7.8 Slide rails

084 7.9 Mounting bearings084 7.10 Lubrication 085 7.11 Fuse rating

086 8. The SI system087 8.1 Quantities and units088 8.2 Prefixes

089 8.3 Conversion factors

092 9. Ordering

093 9.1 Selecting a motor094 9.2 Loading (kW)

095 9.3 Speed

095 9.4 Starting the motor

095 9.5 Operating environment

096 9.6 Ordering and order check list

098 10. Variable speed drives 099 10.1 Types of drives

100 10.2 Pulse Width Modulation100 10.3 Dimensioning the drive102 10.4 Loadability (torque)103 10.4.1 Improving loadability104 10.5 Insulation level

104 10.6 Earthing

105 10.7 Operating at maximum speed107 10.8 Balancing

107 10.9 Critical speeds107 10.10 Shaft seals

0126 10.11 Low speed operation

6 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

— Introduction

This guide provides basic information about IEC lowvoltage motors. In this context, low voltage refers tomotors that operate at voltages less than 1 000 V andproduce a maximum power of 1 000 kW. The referencevalues provided in this guide apply specifically to ABB’sProcess performance motor range.

The designation IEC means that the motors conform tostandards developed by the International ElectrotechnicalCommission. For example, IEC standardizes the frame sizeof motors; in the case of Process performance motors, thereare frame sizes starting from IEC frame 56 in the aluminumrange up to 450 (millimeters from shaft to base) in the castiron motor range. More recently, IEC standards havespecified how motors should be classified into energyefficiency classes.

7

— Introduction

—

1.1. About ABB

ABB is a pioneering technology leader in electrification products,robotics and motion, industrial automation and power grids, servingcustomers in utilities, industry and transport & infrastructure globally.Continuing a history of innovation spanning more than 130 years, ABBtoday is writing the future of industrial digitalization with two clear valuepropositions: bringing electricity from any power plant to any plug andautomating industries from natural resources to finished products. Astitle partner of Formula E, the fully electric international FIA motorsportclass, ABB is pushing the boundaries of e-mobility to contribute to asustainable future. ABB operates in more than 100 countries with about135,000 employees.

ABB’s operations are organized into four global divisions, which in turnare made up of specific business units focused on particular industriesand product categories.

1.1.1. Electrification Products

Technology across the full electrical value chain from substation to thepoint of consumption, enabling safer and more reliable power. A range ofdigital and connected innovations for low- and medium-voltage,including EV infrastructure, solar inverters, modular substations,distribution automation, power protection, wiring accessories,switchgear, enclosures, cabling, sensing and control.

1.1.2. Robotics and Motion

Motors, generators, drives, mechanical power transmission, robotics,wind and traction converters.

1.1.3. Industrial Automation

Products, systems and services designed to optimize the productivity ofindustrial processes. Solutions include turnkey engineering, controlsystems, measurement products, life cycle services, outsourcedmaintenance and industry specific products (eg, electric propulsion forships, mine hoists, turbochargers and pulp testing equipment).

8 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

1.1.4. Power Grids

The Power Grids division offers power and automation products,systems, service and software solutions across the generation,transmission and distribution value chain. Its portfolio includes gridintegration, transmission, distribution and automation solutions and acomplete range of high voltage products and transformers.

—

1.2. IEC low voltage motors

ABB offers wide range of low voltage motors suitable for all industriesand applications, fulfilling all international and national efficiencyregulations.

1.2.1 General performance motors • Cast iron and aluminum motors

1.2.2. Process performance motors• Process performance induction motors• Synchronous reluctance motors• Permanent magnet motors

• High speed motors

• Water cooled motors

9

1.2.3. Motors for explosive atmospheres • Flameproof motors

• Increased safety motors• Non-sparking motors

• Dust ignition proof motors

1.2.4. Motors for industries and specific applications • Marine motors • Mining motors

• Motors for food and beverage• Motors for HVAC industry• Motors for water and wastewater• Brake motors

• High dynamic performance motors• Motors for high ambient temperatures• Roller table motors

• Smoke extraction motors• Stainless steel motors

10 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

—

International motor efficiency

The world industry and commerce are facing an energychallenge. Global demand for energy is rising steadily. Atthe same time, pressures to reduce energy consumption, to lower carbon dioxide (CO

2) emissions and provide secure power supplies are becoming ever stronger.

Efficient motors help cut energy costs and limit carbondioxide emissions. It has been estimated that electricmotors account for about 65 per cent of the electricityconsumed in industrial applications, so the energy-savingpotential among industries is enormous. Energy consumption is dependent on the kW rating of the motor,the dimensioning of the application and the hours run.High-efficiency motors as such can play a significant part

in reducing CO

2 emissions.

ABB is a long-standing advocate of the need for highefficiency in motors and its policy is to offer high-efficiencymotors as standard, available directly from stock. Ratherthan concentrating solely on efficiency, however, we take alifecycle approach and seek to minimize the costs associated with our products over their entire lifetime.

11

—

International motor efficiency

Regulation ECNo 640/2009

|

Energy Efficiency Regulations, Canada |

MKE-2015-28, South-Korea |

|||||||||||||

|

DOE 10 CFR Part 431 (Integral Horsepower Motor Rule), US NOM-016-ENER-2016, Mexico |

JIS 4213, Japan GB18613-2012, China CNS 14400, Taiwan |

|||||||||||||

|

RETIQ, Colombia PRTE-145, Equador RTEE, Peru Chile |

Portaria interministerial No 553, Brazil IRAM 62405, Argentina |

Singapore Indonesia SASO/IEC 60034-30, Saudi-Arabia |

Malaysia Greenhouse and Energy Minimum Standards Act, Australia Energy efficiency and Conservation Authority New Zealand |

|||||||||||

—

2.1 Standards and regulations

Since the validation of IEC 60034-30:2008 and its refined version IEC60034-30-1:2014, a worldwide energy efficiency classification systemhas existed for low voltage three-phase asynchronous motors. Theseinternational standards have been created to enable and increase thelevel of harmonization in efficiency regulations around the world and toalso cover motors for explosive atmospheres.

IEC 60034-30-1:2014 defines International Efficiency (IE) classes for singlespeed, three-phase, 50 Hz and 60 Hz induction motors. The efficiencylevels defined in IEC 60034-30-1 are based on the test method specified inIEC 60034-2-1:2014. Both standards are part of an effort to unify motortesting procedures with CSA390-10 and IEEE 112 standards as well asefficiency and product labeling (IE) requirements to enable motorpurchasers worldwide to easily recognize premium efficiency products.

To promote transparency in the market, IEC 60034-30-1 states that boththe efficiency class and efficiency value must be shown on the motorrating plate and in product documentation. The documentation mustclearly indicate the efficiency testing method used as different methodscan produce differing results.

2.1.1 Minimum energy performance standards

While the IEC as an international standardization organization setsguidelines for motor testing and efficiency classes, the organizationdoes not regulate efficiency levels in countries. The biggest drivers formandatory Minimum Energy Performance Standard (MEPS) levels for

12 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

electric motors are global climate change, government targets to curb CO2 emissions and rising electricity demand, especially in developingcountries. The whole value chain, from manufacturer up to end user, must be aware of the legislation in order to meet local requirements, to saveenergy and reduce the carbon footprint.

Harmonized global standards and the increasing adoption of MEPSaround the world are good news for all of us. However, it is important toremember that harmonization is an ongoing process. Even though MEPSare already in effect in several regions and countries, they are evolvingand differ in terms of scope and requirements. At the same time, morecountries are planning to adopt their own MEPS regulations. A view ofexisting and coming MEPS regulations in the world can be seen on theWorld map in the previous page.

To get the latest information please visit

www.abb.com/motors&generators/energyefficiency.

2.1.2 IEC 60034-30-1:2014

This standard defines four International Efficiency (IE) classes for singlespeed electric motors that are rated according to IEC 60034-1 or IEC60079-0 (explosive atmospheres) and designed for operation onsinusoidal voltage.

• IE4 = Super premium efficiency

• IE3 = Premium efficiency, identical to the table in 10CFR431 (‘NEMA Premium’) in the USA and CSA C390-10:2015 for 60 Hz• IE2 = High efficiency

• IE1 = Standard efficiency

IEC 60034-30-1 covers the power range from 0.12 kW up to 1000 kW.Most of the different technical constructions of electric motors arecovered as long as they are rated for direct on-line operation. Thecoverage of the standard includes:

• Single speed electric motors (single and three-phase), 50 and 60 Hz• 2, 4, 6 and 8 poles

• Rated output PN from 0.12 kW to 1000 kW • Rated voltage UN above 50 V up to 1 kV

• Motors capable of continuous operation at their rated power with a temperature rise within the specified insulation temperature class• Motors, marked with any ambient temperature within the range of -20 °C to +60 °C

• Motors, marked with an altitude up to 4000 m above sea level

13

![]()

![]()

![]()

|

— Figure 2.1 IE Classes – 4-pole motors. |

By comparing IEC 60034-30-1 to CSA C390-10:2015 and “10CFR431 Subpart B – Electric motors”, it can be seen that the efficiency limits and tables are well aligned and their major difference is in the scope of the output power where CSA and 10CFR431 have a maximum power of 500 hp. There are also some minor differences in the scope of excluded motors. |

Note: CFR is Code of Federal Regulations.

The following motors are excluded from IEC 60034-30-1:

• Single-speed motors with 10 or more poles or multi-speed motors• Motors completely integrated into a machine (for example pump, fan or compressor) that cannot be tested separately from the machine• Brake motors, when the brake cannot be dismantled or separately fed

100

90

80

|

70 |

IE4 IE3 IE2 |

IE1

60

|

50 0.12 0.37 0.75 1.5 3 7.5 15 37 90 160 400 1000 |

— Figure 2.1 |

Output kW

2.1.3 ABB and efficiency standards

ABB determines efficiency values according to IEC 60034-2-1 using thelow uncertainty method (i.e. summaration of losses), with additionalload losses determined by the method of residual loss.

It is good to mention and emphasize that the IEC 60034-2-1 test method,which is known as an indirect method, is technically equivalent to thetest methods in the standards CSA 390-10 and IEEE 112 Method B leadingto the equivalent losses and thus efficiency values. Both test methodscan be used by ABB and shall be used for both Canada and the US whereIEC 60034-2-1 is not recognized yet.

As the world market leader, ABB offers the largest range of LV motorsavailable. It has long advocated the need for efficiency in motors, andhigh efficiency products have formed the core of its portfolio for manyyears. The core of ABB’s Process performance range is based on a fullrange of IE2 and IE3 motors – with many available from stock. We alsosupply IE4 motors for additional energy savings.

14 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

Nominal efficiency limits defined in IEC 60034-30-1:2014

(reference values at 50 Hz, based on test methods specified in IEC 60034-2-1:2014).

|

Out- put |

IE1 Standard efficiency |

IE2 High efficiency |

IE3 Premium efficiency |

IE4 Super Premium efficiency |

|||||||||||||||||||||||||||||

|

kW |

2 pole |

4 pole |

6 pole |

8 pole |

2 pole |

4 pole |

6 pole |

8 pole |

2 pole |

4 pole |

6 pole |

8 pole |

2 pole |

4 pole |

6 pole |

8 pole |

|||||||||||||||||

0.12 45.0 50.0 38.3 31.0 53.6 59.1 50.6 39.8 60.8 64.8 57.7 50.7 66.5 69.8 64.9 62.3

0.18 52.8 57.0 45.5 38.0 60.4 64.7 56.6 45.9 65.9 69.9 63.9 58.7 70.8 74.7 70.1 67.2

0.20 54.6 58.5 47.6 39.7 61.9 65.9 58.2 47.4 67.2 71.1 65.4 60.6 71.9 75.8 71.4 68.4

0.25 58.2 61.5 52.1 43.4 64.8 68.5 61.6 50.6 69.7 73.5 68.6 64.1 74.3 77.9 74.1 70.8

0.37 63.9 66.0 59.7 49.7 69.5 72.7 67.6 56.1 73.8 77.3 73.5 69.3 78.1 81.1 78.0 74.3

0.40 64.9 66.8 61.1 50.9 70.4 73.5 68.8 57.2 74.6 78.0 74.4 70.1 78.9 81.7 78.7 74.9

0.55 69.0 70.0 65.8 56.1 74.1 77.1 73.1 61.7 77.8 80.8 77.2 73.0 81.5 83.9 80.9 77.0

0.75 72.1 72.1 70.0 61.2 77.4 79.6 75.9 66.2 80.7 82.5 78.9 75.0 83.5 85.7 82.7 78.4

1.1 75.0 75.0 72.9 66.5 79.6 81.4 78.1 70.8 82.7 84.1 81.0 77.7 85.2 87.2 84.5 80.8

1.5 77.2 77.2 75.2 70.2 81.3 82.8 79.8 74.1 84.2 85.3 82.5 79.7 86.5 88.2 85.9 82.6

2.2 79.7 79.7 77.7 74.2 83.2 84.3 81.8 77.6 85.9 86.7 84.3 81.9 88.0 89.5 87.4 84.53 81.5 81.5 79.7 77.0 84.6 85.5 83.3 80.0 87.1 87.7 85.6 83.5 89.1 90.4 88.6 85.94 83.1 83.1 81.4 79.2 85.8 86.6 84.6 81.9 88.1 88.6 86.8 84.8 90.0 91.1 89.5 87.1

5.5 84.7 84.7 83.1 81.4 87.0 87.7 86.0 83.8 89.2 89.6 88.0 86.2 90.9 91.9 90.5 88.3

7.5 86.0 86.0 84.7 83.1 88.1 88.7 87.2 85.3 90.1 90.4 89.1 87.3 91.7 92.6 91.3 89.311 87.6 87.6 86.4 85.0 89.4 89.8 88.7 86.9 91.2 91.4 90.3 88.6 92.6 93.3 92.3 90.415 88.7 88.7 87.7 86.2 90.3 90.6 89.7 88.0 91.9 92.1 91.2 89.6 93.3 93.9 92.9 91.2

18.5 89.3 89.3 88.6 86.9 90.9 91.2 90.4 88.6 92.4 92.6 91.7 90.1 93.7 94.2 93.4 91.722 89.9 89.9 89.2 87.4 91.3 91.6 90.9 89.1 92.7 93.0 92.2 90.6 94.0 94.5 93.7 92.130 90.7 90.7 90.2 88.3 92.0 92.3 91.7 89.8 93.3 93.6 92.9 91.3 94.5 94.9 94.2 92.737 91.2 91.2 90.8 88.8 92.5 92.7 92.2 90.3 93.7 93.9 93.3 91.8 94.8 95.2 94.5 93.145 91.7 91.7 91.4 89.2 92.9 93.1 92.7 90.7 94.0 94.2 93.7 92.2 95.0 95.4 94.8 93.455 92.1 92.1 91.9 89.7 93.2 93.5 93.1 91.0 94.3 94.6 94.1 92.5 95.3 95.7 95.1 93.775 92.7 92.7 92.6 90.3 93.8 94.0 93.7 91.6 94.7 95.0 94.6 93.1 95.6 96.0 95.4 94.290 93.0 93.0 92.9 90.7 94.1 94.2 94.0 91.9 95.0 95.2 94.9 93.4 95.8 96.1 95.6 94.4110 93.3 93.3 93.3 91.1 94.3 94.5 94.3 92.3 95.2 95.4 95.1 93.7 96.0 96.3 95.8 94.7132 93.5 93.5 93.5 91.5 94.6 94.7 94.6 92.6 95.4 95.6 95.4 94.0 96.2 96.4 96.0 94.9160 93.8 93.8 93.8 91.9 94.8 94.9 94.8 93.0 95.6 95.8 95.6 94.3 96.3 96.6 96.2 95.1200 94.0 94.0 94.0 92.5 95.0 95.1 95.0 93.5 95.8 96.0 95.8 94.6 96.5 96.7 96.3 95.4250 94.0 94.0 94.0 92.5 95.0 95.1 95.0 93.5 95.8 96.0 95.8 94.6 96.5 96.7 96.5 95.4315 94.0 94.0 94.0 92.5 95.0 95.1 95.0 93.5 95.8 96.0 95.8 94.6 96.5 96.7 96.6 95.4355 94.0 94.0 94.0 92.5 95.0 95.1 95.0 93.5 95.8 96.0 95.8 94.6 96.5 96.7 96.6 95.4400 94.0 94.0 94.0 92.5 95.0 95.1 95.0 93.5 95.8 96.0 95.8 94.6 96.5 96.7 96.6 95.4450 94.0 94.0 94.0 92.5 95.0 95.1 95.0 93.5 95.8 96.0 95.8 94.6 96.5 96.7 96.6 95.4 500-

1000 94.0 94.0 94.0 92.5 95.0 95.1 95.0 93.5 95.8 96.0 95.8 94.6 96.5 96.7 96.6 95.4

15

—

2.2 Life cycle approach and energy appraisal

To achieve the best return on investment, users of production equipmentneed to apply a life cycle approach when considering investing in majorequipment. The life cycle cost (LCC) is the total cost for purchasing,installing, operating, maintaining and disposing of an item of machinery.

It is necessary to raise awareness of the financial benefits of energyefficiency. Payback times of an item of machinery can be extremely shortbut many businesses still focus on the purchase price when buying newequipment, instead of considering running costs over the lifespan.

The purchase price of an electric motor and drive, for instance, is just 1-3per cent of what the owner will spend on energy to run the equipmentover its lifetime. The significance of a variable speed drive in efficiencyconsiderations is in its quality to control the speed of the motor andtherefore ensure that it runs no faster than actually needed.

LCC should be calculated not only on new installations but also existingones. Existing systems provide much greater scope for efficiencyimprovements than new installations. The volume of systems in useexceeds the volume of annual new installations many times over.Additionally, many existing installations can offer considerable scope forimprovement if the duty has changed since the system was firstinstalled.

2.2.1 Energy appraisal

ABB has devised a simple and methodical energy appraisal process thatpresents the energy saving potential of selected applications to the endusers. The starting point for an energy appraisal is to indentifyapplications where energy can be saved immediately.

Energy appraisals are most suitable for processes with variable torqueapplications that obey the cube law, run continuously, and where the flowis controlled by a mechanical means such as valves or dampers. This iswhere the savings from installing a variable speed drive typically are themost significant compared to the initial investment cost.

16 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

—

2.3 Environmental management within ABB

2.3.1 ISO 14001

To ensure continual improvement, ABB requires all manufacturing andservice facilities to implement environmental management systemsaccording to the ISO 14001 standard. For non-manufacturing sites wehave implemented and adapted an environmental management systemto ensure management of environmental aspects and continualperformance improvement. Almost all of these approximately 360 sitesand offices work in compliance with the requirements of the standardand our environmental management program now covers operations in59 countries. It is ABB’s aim to further advance the adaptation ofenvironmental management systems among our suppliers.

2.3.2 Hazardous substances

The use of chemicals in society has increased significantly in recentdecades. Concern about the negative effects of hazardous substanceshas resulted in stricter legal frameworks in many countries. Full controlof hazardous substances in our products and processes is thereforebusiness critical.

ABB is committed to phasing out the use of hazardous substances in ourproducts and processes, where technically and economically feasible. Wehave developed lists of prohibited and restricted substances to guidethis process and update them regularly, in line with developments ininternational regulations. Such restrictions include for examplecomponents containing brominated flame retardants, PCB, PCT ormercury, or the use of cadmium in surface treatment.

2.3.3 Materials selection

Some of the sustainability activities concerning motor production arethe guidelines for selecting construction materials:• Aim at minimizing the quantity of materials in order to reduce the weight of the product.

• Reduce the number of different materials in the product.• Minimize the number of components used in the product and select as small components as possible.

• Choose recycled materials or a combination of virgin and recycled material for the product instead of virgin material, if possible.• When using virgin materials, choose materials that are recyclable.• Prefer materials for which recovery and recycling systems have been established, such as steel, aluminum, and unmixed thermoplastics.

17

2.3.4 EU Directive 2012/19/EU (WEEE)

The scope of the European directive 2012/19/EU for Waste Electrical &Electronic Equipment (WEEE) will extent to so called open scope fromAugust 15, 2018. This means that also electric motors can be consideredas affected by this directive.

Different member countries in EU and motor manufacturers have takendifferent approach in this question, some consider motors to be includedand some not, and some only up to certain size.

Within our PG have we taken the decision to start marking most of theproducts that are produced and can be imported to Europe as describedin the directive. There is also a specific recycling instruction preparedthat will be delivered with the products.

18 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

— Standards

ABB Motors and Generators build motors and generatorsto comply with international IEC and CENELEC standards.Within the European Union, ABB takes into accountrelevant EU-regulations, VDE-regulations, and DIN-standards. Motors conforming to other national andinternational specifications are also available.

All ABB motor production units are ISO 14001 certified andconform to applicable EU directives.

ABB strongly supports the drive to harmonize internationalstandards and actively contributes to various technicalcommittees and working groups within IEC, CENELEC andIECEx system.

19

— Standards

—

3.1 Definitions

Directive

A legislative act of the European Union to achieve a particular result inthe EU member states.

Standard

A specifications document established as a result of consensus betweeninternational technical experts working for a standards organizationsuch as the International Electrotechnical Commission (IEC), theEuropean Committee for Electrotechnical Standardization (CENELEC), ora national standards organization (NEMA in the US, DKE in Germany).

Adoption of IEC standards by any country or manufacturer is voluntarybut preferred and mandatory when following the IECEx scheme.

Harmonized standard

A standard that provides conformity with corresponding requirements ofan EU directive to demonstrate compliance with EU legislation.

Harmonized standards are published online under European Union’swebsite as well as in the Official Journal (OJ) of the European Union.Their application is mandatory to the extent that a correspondingdirective requires.

20 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

—

3.2 Standards tables

The following tables serve as reference lists for electrical and mechanicalstandars that apply to most induction motors depending on motor typeand type of protection.

3.2.1 The main standards for low voltage motors

Electrical Title

IEC / EN 60034-1 Rating and performance

IEC / EN 60034-2-1 Standard methods for determining losses and efficiency from tests

(excluding machines for traction vehicles)

IEC / EN 60034-2-2 Specific methods for determining separate losses of large machines

from tests – Supplement to IEC 60034-2-1

IEC 60034-2-3 Rotating electrical machines – Part 2–3: Specific testing methods for

determining losses and efficiency of converter-fed AC inductionmotors.

IEC / EN 60034-8 Terminal markings and direction of rotation

IEC / EN 60034-12 Starting performance of single-speed three-phase cage induction

motors

IEC / TS 60034-25 Guidance for the design and performance of AC motors specifically

designed for converter supply

IEC / EN 60034-26 Effects of unbalanced voltages on the performance of three-phase

cage induction motors

IEC / EN 60034-30 Efficiency classes of single-speed three-phase cage induction motors

(IE-Code)

|

IEC / TS 60034-31 CLC/TS 60034-31 |

Selection of energy-efficient motors including variable speed applications – Application guide |

IEC 60038 IEC standard voltages

IEC 60050-411 International electrotechnical vocabulary – Chapter 411: Rotating

machines

Mechanical Title

IEC / EN 60034-5 Degrees of protection provided by the integral design of rotating

electrical machines (IP code) – Classification

IEC / EN 60034-6 Methods of cooling (IC code)

IEC / EN 60034-7 Classification of types of construction, mounting arrangements and

terminal box position (IM Code)

IEC / EN 60034-9 Noise limits

IEC / EN 60034-14 Mechanical vibration of certain machines with shaft heights 56 mm and

higher – Measurement, evaluation and limits of vibration severity

IEC / EN 60072-1 Dimensions and output series for rotating electrical machines

Part 1: Frame sizes 56 to 400 and flange numbers 55 to 1080

IEC / EN 60529 Degree of protection provided by enclosure (IP Code)

EN 50102 Degrees of protection provided by enclosures for electrical equipment

against external mechanical impacts (IK code)

EN 50347 General purpose three-phase induction motors having standard dimensions and outputs – Frame sizes 56 to 315 and flange numbers 65 to 740

ISO 21940-32 Mechanical vibration – rotor balancing – Part 32: Shaft and fitment key

convention

21

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Specific applications in addition to the standards above

Smoke extraction motors Title

EN 12101-3 Smoke and heat control systems Specification for powered smoke and

heat exhaust ventilators

Hazardous areas Title

IEC / EN 60079-0 Equipment – General requirements

IEC / EN 60079-1 Equipment protection by flameproof enclosures “d”

IEC / EN 60079-7 Equipment protection by increased safety “e”

IEC / EN 60079-31 Equipment dust ignition protection by enclosure “t”

IEC / EN 60079-14 Electrical installations design, selection and erection

IEC / EN 60079-17 Electrical installations inspections and maintenance

IEC / EN 60079-19 Equipment repair, overhaul and reclamation

IEC / EN 60050-426 International electrotechnical vocabulary- Part 426:

Equipment for explosive atmospheres

IEC / EN 60079-10-1 Classification of areas – Explosive gas atmospheres

IEC / EN 60079-10-2 Classification of areas – Combustible dust atmospheres

3.2.2 The main EU directives for motors

Directive Field of application

|

2014/34/EU ‘ATEX’ |

Equipment and protective systems intended for use in potentially explosive atmospheres |

||||||

|

1999/92/EC ‘Worker Directive’ |

Minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres |

||||||

|

2014/35/EU ‘Low Voltage Directive’ |

Making available on the market of electrical equipment designed for use within certain voltage limits (except for those used in potentially explosive atmospheres) |

||||||

|

2009/125/EC ‘Ecodesign Directive’ |

Framework for the setting ecodesign requirements for energy-related products (ErP) |

||||||

|

EU Regulation 640/2009 and amending Regulation 4/2014 |

Implementing Directive 2005/32/EC of the European Parliament and of the Council with regard to ecodesign requirements for electric motors |

||||||

3.2.3 Efficiency determination for motors outside Europe

|

USA IEEE 112-B CSA C390-10 |

Test procedure for polyphase induction motors and generators Test methods, marking requirements, and energy efficiency levels for tree-phase induction motors |

Canada CSA C390-10 Test methods, marking requirements, and energy efficiency

levels for tree-phase induction motors

China GB/T 1032: 2005 Test methods for induction motors; includes methods

identical to IEC 60034-2-1: 2007 with segregated losses

India IS 12615: 2011 Methods identical to IEC 60034-2-1: 2007

(in line with IEC 60034-30: 2008)

|

Brazil ABNT NBR 17094-1:2013 |

Three-phase induction motors – Tests |

|||||

|

Australia, New Zealand |

AS/NZS 1359.102.3 or IEC 60034-2-1 AS/NZS 1359.102.1 or IEC 60034-2 |

Method A for determining losses and efficiency – Three-phase cage induction motors Method B for determining losses and efficiency – Three-phase cage induction motors |

||||

22 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

—

3.3 Direction of rotation

Motor cooling is independent of the direction of rotation, except forcertain larger two-pole motors.

When the mains supply is connected to stator terminals marked U, V, andW of a three-phase motor and the mains phase sequence is L1, L2, L3, themotor will rotate clockwise, as viewed from the D-end. The direction ofrotation can be reversed by interchanging any two of the threeconductors connected to a starter switch or motor.

N-end

D-end

23

—

3.4 Cooling

A designation system concerning the method of cooling is based on thestandard IEC 60034-6.

Example

IC 4 (A) 1 (A) 6

International Cooling

Circuit arrangement

0: Free circulation (open circuit)4: Frame surface cooled

Primary coolant

A for air (omitted for simplified designation)

Method of movement of primary coolant 0: Free convection 1: Self-circulation

6: Machine-mounted independent component

Secondary coolant

A for air (omitted for simplified designation)W for water

Method of movement of secondary coolant 0: Free convection 1: Self-circulation

6: Machine-mounted independent component8: Relative displacement

ABB can deliver motors with the following cooling options.

IC 410: totally enclosed motors without a fan

IC 411: totally enclosed standard motors, frame-surface cooled with a fanIC 416: totally enclosed motors with an auxiliary fan motor

IC 418: totally enclosed motors, frame -surface cooled without a fanIC 31W: inlet and outlet pipe or duct circulated: water-cooled motors

Note:

Motors without a fan can deliver the same output power as those witha standard configuration (with a fan of their own) when installed according toIC 418.

24 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

![]()

—

3.5 Degrees of protection: IP code/IK code

Classifications of the degrees of protection provided by enclosures ofrotating machines are based on:

• IEC / EN 60034-5 or IEC / EN 60529 for IP code

• IK code acc. to EN 50102 for standard motors. Impact test acc. to IEC 60079-0 for motors in hazardous atmospheres.

IP protection:

Protection of persons against getting in contact with (or approaching) liveparts and against contact with moving parts inside the enclosure. Alsoprotection of the machine against the ingress of solid foreign objects.Protection of machines against the harmful effects of the ingress of water.

IP 5 5

Characteristic letter

Degree of protection to persons and to parts of the motors inside the enclosure

2: Motors protected against solid objects greater than 12 mm4: Motors protected against solid objects greater than 1 mm5: Dust-protected motors

6: Dust-tight motors

Degree of protection provided by the enclosure withrespect to harmful effects due to ingress of water3: Motors protected against spraying water4: Motors protected against splashing water5: Motors protected against water jets 6: Motors protected against heavy seas

9: Motors protected against close-range high pressure, high temperature spray downs

IK code:

Classification of degrees of protection provided by enclosure for motorsagainst external mechanical impacts.

IK 05

International mechanical protection

Characteristic group

Relation between IK code and impact energy

IK code IK 00 IK 01 IK 02 IK 03 IK 04 IK 05 IK 06 IK 07 IK 08 IK 09 IK 10

Impact * 0.15 0.2 0.35 0.5 0.7 1 2 5 10 20

Energy ABB Standard

Joule

*not protected according to EN 50102

25

![]()

![]()

![]()

![]()

![]()

—

3.6 Standard voltage ranges

ABB provides motors for markets worldwide. To be able to meetcustomers’ requirements, motors are designed for operation over a widerange of voltages. The most common voltage codes are S, D, E, and F.These cover the most common voltages used worldwide. Other voltageranges are available on request.

The following table covers the most common voltage ranges.

Direct-on-line start or, with Δ-connection, also Y/Δ-start

Motor size S D

50 Hz 60 Hz 50 Hz 60 Hz

56-100 220-240 VΔ – 380-415 VΔ 440-480 VΔ

380-415 VY 440-480 VY 660-690 VY –

112-132 220-240 VΔ – 380-415 VΔ 440-480 VΔ

380-415 VY 440-480VY 660-690 VY –

160-4501) 220, 230 VΔ 380, 400, 415 YΔ 440-480 VΔ

380, 400, 415 VY 440 VY 660 VY –

Motor size E F

50 Hz 60 Hz 50 Hz 60 Hz

56-100 500 VΔ 2) 500 VY 2)

112-132 500 VΔ 2) 500 VY 2)

160-450 500 VΔ 2) 2) 2)

A chart of world voltages can be obtained from from an ABB motors sales office.

1) The voltage range varies from type to type. Check the valid values in relevant product catalogs.2) On request.

Motors for other voltages

Motors wound for a given voltage at 50 Hz can also be used for othervoltages. Efficiency, power factor, and speed remain approximately thesame. Exact motor-specific values are available on request.

Motor wound for 230 V 400 V 500 V 690 V

Connected to (50 Hz) 220 V 230 V 380 V 415 V 500 V 550 V 660 V 690 V

|

% of values in a 400 V, 50 Hz network |

% of values in a 400 V, 50 Hz network |

% of values in a 400 V, 50 Hz network |

% of values in a 400 V, 50 Hz network |

Output 100 100 100 100 100 100 100 100

IN 180 174 105 98 80 75 61 58

IS/IN 90 100 90 106 100 119 90 100

T

S/TN 90 100 90 106 100 119 90 100

T

max/TN 90 100 90 106 100 119 90 100

26 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

|

— Figure 3.1 Voltage and frequency deviation in zones A and B. |

— 3.7 Voltage and frequency The impact on temperature rise caused by voltage and frequency fluctuation is defined in IEC 60034-1. The standard divides the combinations into two zones, A and B. Zone A is the combination of voltage deviation of +/-5 % and frequency deviation of +/-2 %. Zone B is the combination of voltage deviation of +/-10 % and frequency deviation of +3/-5 %. This is illustrated in figure 3.1. |

1 3 2 |

0.95 0.98 |

Y 1.10 1.05 1.03 1.09 X 1.00 1.02 0.93 0.95 |

||||||||

|

Motors are capable of supplying the rated torque in both zones A and B, but the temperature rise will be higher than at rated voltage and frequency. Motors can be run in zone B only for a short period of time. |

0.90 Key X axis frequency p.u. Y axis voltage p.u. 1 zone A 2 zone B (outsice zone A) 3 rating point |

|||||||||||

|

— 3.8 Tolerances |

— Figure 3.1 |

|||||||||||

In accordance with IEC 60034-1, tolerance is the maximum alloweddeviation between the test result and the declared value on the ratingplate (or in the catalog). Test results are based on test procedures inaccordance with IEC 60034-2-2 and IEC 60034-2-3.

|

Efficiency Power factor |

Locked rotor current |

Locked rotor torque |

Pull-up torque |

Moment of inertia |

Noise level |

||||||||||||||||||||||||||

|

PN (kW) ≤ 150 |

-15 % (1-η) |

-1/6 (1-cosϕ) |

+20 % of the current |

[-15 %+25 %] of the torque |

-15 % of the value |

± 10 % of the value |

+3 dB(A) |

||||||||||||||||||||||||

|

PN (kW) > 150 |

-10 % (1-η) Slip |

-1/6 (1-cosϕ) |

+20 % of the current |

[-15 %+25 %] of the torque |

-15 % of the value |

± 10 % of the value |

+3 dB(A) |

||||||||||||||||||||||||

|

PN (kW) < 1 |

± 30 % |

||||||||||||||||||||||||||||||

|

PN (kW) ≥ 1 |

± 20 % |

||||||||||||||||||||||||||||||

27

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

—

3.9 Mounting arrangements International standards

IM mounting arrangements

Example of designations according to Code II

IM 1 00 1

Designation for international mounting

Type of construction, foot-mountedmotor with two bearing end shields

Mounting arrangement, horizontalmounting with feet downwards etc.

External shaft extension, onecylindrical shaft extension etc.

Examples of common mounting arrangements

Code I IM B3 IM V5 IM V6 IM B6 IM B7 IM B8

Code II IM 1001 IM1011 IM 1031 IM1051 IM 1061 IM 1071

Foot-motor

Code I IM B5 IM V1 IM V3 *) *) *)

Code II IM 3001 IM 3011 IM3031 IM 3051 IM 3061 IM 3071

Flange- mounted motor, largeflange withclearance fixing holes.

Code I IM B14 IM V18 IM V19 *) *) *)

Code II IM 3601 IM 3611 IM 3631 IM 3651 IM 3661 IM 3671

Flange- mounted motor, smallflange withtapped fixing holes.

*) Not stated in IEC 60034-7

28 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

—

3.10 Dimensions International standards

IM mounting arrangements

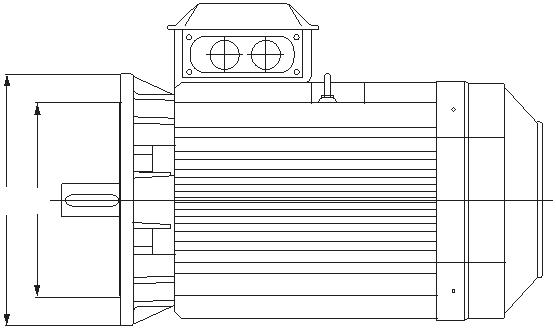

This is a sample of a typical dimension drawing. Dimension drawings areavailable in catalogs, and on the ABB web site.

L

HD

H

E C B

K

|

B’ |

A |

M

D S F

45°GA

29

M S

P N

45°

Letter symbols for the most common dimensions:

|

A = distance between center lines of fixing holes (end view) |

F = width of the keyway of the shaft extension at D-end |

L = overall length of the motor with a single shaft extension |

||||

|

B = distance between the center lines of the fixing holes (side view) B’ = distance between the center lines of the auxiliary fixing holes C = distance of the shoulder on the shaft at D-end to the center line of the mounting holes in the nearest feet D = diameter of the shaft extension at D-end |

GA = distance from the top of the key to the opposite surface of the shaft extension at D-end H = distance from the centre line of the shaft to the bottom of the feet HD= distance from the top of the lifting eye, the terminal box, or other most salient part mounted on the top of the motor to the bottom of the feet |

M = pitch circle diameter of the fixing holes N = diameter of the spigot P = outside diameter of the flange, or in the case of a non-circular outline twice the maximum radial dimension S = diameter of the fixing holes in the mounting flange, or nominal diameter of thread. |

||||

|

E = length of the shaft extension from the shoulder at the D-end |

K = diameter of the holes or width of the slots in the feet of the motor |

|||||

30 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

![]()

|

— Table 3.1 Power – frame size correlation according to CENELEC |

— 3.11 Output power and frame size ratio Several countries have implemented a minimum energy efficiency performance standard (MEPS) through national legislation. IEC sets guidelines for testing and classification of motors according to standards. The following tables present two applications of power vs. frame size standards, one for Europe and another for Brazil. |

In Europe, the CENELEC standard EN 50347 lays down data for ratedoutput and mounting, i.e. shaft height, fixing dimensions and shaftextension dimensions, for various degrees of protection and sizes. Itcovers totally enclosed fan-cooled squirrel-cage motors at 50 Hz, framesizes 56 M to 315 M.

Standard output

|

Frame size |

Shaft extension diameter |

Rated output Flange number |

|||||||||||||||||||||||||||||||||

|

2 poles mm |

4,6,8 poles mm |

2 poles kW |

4 poles kW |

6 poles kW |

8 poles kW |

Free holes (FF) |

Tapped holes (FT) |

||||||||||||||||||||||||||||

|

56 9 9 0.09 or 0.12 |

0.06 or 0.09 |

F100 F65 |

|||||||||||||||||||||||||||||||||

|

63 11 11 0.18 or 0.25 |

0.12 or 0.18 |

F115 F75 |

|||||||||||||||||||||||||||||||||

|

71 14 14 0.37 or 0.55 |

0.25 or 0.37 |

F130 F85 |

|||||||||||||||||||||||||||||||||

|

80 19 19 0.75 or 1.1 |

0.55 or 0.75 |

0.37 or 0.55 |

F165 F100 |

||||||||||||||||||||||||||||||||

90S 24 24 1.5 1.1 0.75 0.37 F165 F115

90L 24 24 2.2 1.5 1.1 0.55 F165 F115

|

100L 28 28 3 2.2 or 3 1.5 0.75 or 1.1 |

F215 F130 |

112M 28 28 4 4 2.2 1.5 F215 F130132S 38 38 5.5 or 7.5 5.5 3 2.2 F265 F165132M 38 38 – 7.5 4 or 5.5 3 F265 F165160M 42 42 11 or 15 11 7.5 4 or 5.5 F300 F215 160L 42 42 18.5 15 11 7.5 F300 F215 180M 48 48 22 18.5 – – F300 180L 48 48 – 22 15 11 F300

200L 55 55 30 or 37 30 18.5 or 15 F350 22

225S 55 60 – 37 – 18.5 F400225M 55 60 45 45 30 22 F400250M 60 65 55 55 37 30 F500280S 65 75 75 75 45 37 F500280M 65 75 90 90 55 45 F500315S 65 80 110 110 75 55 F600315M 65 80 132 132 90 75 F600

—

Table 3.1

31

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

— Table 3.2 Power – frame size correlation according to NBR |

Brazil requires that motors imported to Brazil comply with national ABNT NBR 17094-1:2013 standards for low voltage motors. NBR 17094-1:2008 defines the frame-power relation as shown in the table below. Power kW Frame HP 2 poles 4 poles 6 poles 8 poles 0.18 0.25 63 63 71 71 0.25 0.33 63 63 71 80 0.37 0.50 63 71 80 90S 0.55 0.75 71 71 80 90L 0.75 1 71 80 90S 90L 1.1 1.5 80 80 90S 100L 1.5 2 80 90S 100L 112M 2.2 3 90S 90L 100L 132S 3.0 4 90L 100L 112M 132M 3.7 5 100L 100L 132S 132M 4.7 6 112M 112M 132S 160M 5.5 7.5 112M 112M 132M 160M 7.5 10 132S 132S 132M 160L 9.2 12.5 132S 132M 160M 180M/L 11.0 15 132M 132M 160M 180L 15.0 20 160M 160M 160L 180L 18.5 25 160M 160L 180L 200L 22 30 160L 180M 200L 225S 30 40 200M 200M 200L 225M 37 50 200L 200L 225M 250S 45 60 225S 225S 250S 250M 55 75 225M 225M 250M 280S 75 100 350M 250M 280S 280M 90 125 280S 280S 280M 315M 110 150 280M 280M 315M 315M 132 175 315S 315S 315M 355 150 200 315S 315S 315M 355 185 250 315S 315M 355 355 220 300 355 355 355 355 260 350 355 355 355 355 300 400 – 355 355 – 330 450 – 355 355 – 370 500 – 355 – – |

—

Table 3.2

32 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

—

Electrical design – induction motors

The electrical and mechanical design chapters of thisguide focus on induction motors.

Designing motors that deliver good all-round performanceinvolves a delicate balance between a number of factorswhich include efficiency, cost, temperature rise, vibration,noise, bearing selection, and slot and fan design. Only thecorrect balance will result in high quality motors which areefficient and reliable and provide a long service life.

33

—

Electrical design – induction motors

—

4.1 The induction motor

ABB’s low voltage induction motors are three-phase electric motorswhose rotating power is based on electromagnetic induction. Thecurrent led to motor windings creates a rotating magnetic field, whichinduces a voltage in the rotor bars. The bars form a closed circuit wherecurrent begins to circulate, forming another magnetic field. Themagnetic fields of the rotor and stator interact in such a way that therotor starts following the magnetic field of the stator, thus producingtorque.

In the nature of asynchronous motors, the rotor tends to fall behind thespeed of the magnetic field in the stator. When mechanical loadincreases on the motor shaft, the difference in speed (slip) increases, anda higher torque is produced.

ABB’s low voltage induction motors cover the power range from 0.06 to1000 kW.

34 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

![]()

|

— Figure 4.1 Safety margins per insulation class |

— 4.2 Insulation |

ABB uses class F insulation, which, with temperature rise class B, is themost commonly required insulation system for industrial motors.

Thermal class 130 (B)

• Nominal ambient temperature 40°C• Max. permissible temperature rise 80 K• Hot spot temperature margin 10 K

Thermal class 155 (B)

• Nominal ambient temperature 40°C• Max. permissible temperature rise 105 K• Hot spot temperature margin 10 K

Thermal class 180 (H)

• Nominal ambient temperature 40°C• Max. permissible temperature rise 125 K• Hot spot temperature margin +15 K

The use of class F insulation with class B temperature rise gives ABBproducts a 25 °C safety margin. This can be exploited to increase theloading of the motor for limited periods, to operate at higher ambienttemperatures or altitudes or with greater voltage and frequencytolerances. It can also be exploited to extend insulation life. For instance,already a 10 K temperature reduction has a relevant effect on insulationlifetime.

C

|

180 |

15 |

||||||||||||

|

155 130 120 |

Hotspot temperature margin |

10 |

10 |

||||||||||

|

Permissible temperature rise |

80 105 125 |

||||||||||||

40

|

Maximum ambient temperature |

40 40 40 |

||||||

|

Insulation class Maximum winding temperature |

B F H 130 155 180 |

||||||

—

Figure 4.1

35

![]()

![]()

![]()

![]()

![]()

![]()

|

— Table 4.1 Permitted output in high ambient temperatures or at high altitudes |

— 4.3 Thermistors Thermistors are temperature-dependent resistors inserted inside the winding heads − one for each phase − to control motor temperature. Under a certain temperature, the thermistor shows a fairly constant low resistance, but from a certain temperature upwards this resistance dramatically increases and the relay connected to thermistors will act. The resistance change is transformed into connection signals (warning or disconnection) resulting in thermal machine protection. |

—

4.4 Ambient temperatures and high altitudes

Normal motors are designed for operation at a maximum ambienttemperature of 40 °C and at a maximum altitude of 1000 meters abovesea level. If a motor is operated at higher ambient temperatures, it shouldbe derated according to the table below. Note that when the output power of a standard motor is derated, the relative values, such as IS/IN, incatalogs will change.

Ambient Temperature, °C 30 40 45 50 55 60 70 80

Permitted output, % of rated output 107 100 96.5 93 90 86.5 79 70

Height above sea level, m 1000 1500 2000 2500 3000 3500 4000

Permitted output, % of rated output 100 96 92 88 84 80 76

—

Table 4.1

36 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

—

4.5 Starting methods

The most common motor starting methods are introduced next. Theyare: direct-on-line and star-delta starting, and starting with a softstarteror variable speed drive.

Connection transients

It is important to remember that the term ‘starting current’ refers to asteady-state root-mean-square (rms) value. This is the value measuredwhen, after a few cycles, the transient phenomena have died out. Thepeak value of the transient current may be about 2.5 times the steady-state starting current, but decays rapidly. The starting torque of themotor behaves similarly, and this should be borne in mind if the momentof inertia of the driven machine is high, since the stresses on the shaftand coupling can be great.

4.5.1 Direct-on-line (DOL) starting

The simplest way to start a squirrel cage motor is to connect it directly tothe mains supply. In this case, a switch gear e.g. a contactor is the onlystarting equipment required. However, the limitation of this method is thatit results in a high starting current, often several times the rated current ofthe motor. Also the starting torque is very high, and may result in highstresses on the couplings and the driven application. Even so, it is thepreferred method except when there are special reasons for avoiding it.

4.5.2 Star-delta starting

If it is necessary to restrict the starting current of a motor because ofsupply limitations, the star-delta (Y/Δ) method can be employed. When amotor wound for 400 V/Δ, for instance, is started with winding Yconnected, this method will reduce the starting current to about 30 percent of the current reached with DOL, and the starting torque will bereduced to about 25 per cent of its DOL value.

However, before using this method, it must be determined whether thereduced motor torque is sufficient to accelerate the load over themotor’s speed range.

Contact your nearest ABB sales office for the MotSize dimensioning tool,or download it from our web site. ABB offers a full range of low voltageproducts for motor starting and control.

37

|

A sample taken from a dimensioning program showing DOL starting curves for a cast iron motor: 1. Starting torque at U n 2. Starting torque at 80 % U n 3. Torque load |

A sample taken from a dimensioning program showing Y/Δ starting curves for an aluminum motor: 1. Starting torque at U n 2. Starting torque at 80 % U n 3. Torque load |

|||||

|

— Figure 4.2 |

— Figure 4.3 |

|||||

|

— Figure 4.2 DOL starting — Figure 4.3 Star- delta starting |

4.5.3 Softstarters A softstarter limits the starting current of the motor and so provides a smooth start. The magnitude of the starting current is directly dependent on the static torque requirement during a start and on the mass of the load to be accelerated. ABB softstarters have adjustable settings to meet any application requirements. Gradually increasing the motor voltage, and thereby torque, results in a very smooth start. When the motor is well up in speed, it is common to bypass the softstarter to avoid power loss from the semiconductors during continuous operation. To bypass the softstarter it is common to use an externally mounted, AC-1 rated contactor. |

|||||

A bypass contact can also be built into the softstarter like in ABB’ssoftstarter ranges PSR, PSE, and PSTB. These softstarters are among themost compact available in the market.

In the ABB softstarter, the main circuit is controlled by semiconductorsinstead of mechanical contacts. Each phase is provided with two anti-parallel connected thyristors, which allows current to be switched at anypoint within both positive and negative half-cycles.

Lead time is controlled by the firing angle of the thyristor which, in turn,is controlled by a built-in printed circuit board.

38 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

|

— Figure 4.4 Impact of softstarters on current and torque |

Current Torque DoL DoL Y/ |

Y/ |

|||||||

|

— Figure 4.5 ABB softstarters |

Softstart |

Softstar |

|||||||

—

Figure 4.4

—

Figure 4.5

4.5.4 Starting with a variable speed drive

Speed regulation by a variable speed drive is a great advantage whenthere is need to adjust speed during continuous run, but it is usually notthe optimal solution only for starting and stopping the motor.

With a frequency converter, the rated motor torque is available already ata low speed, and the starting current is low, between 0.5 and 1 timesrated motor current, and at maximum 1.5 times nominal current. Anotheravailable feature in drives is softstop, which is useful when a smoothstop is equally desirable as a smooth start, for example in operatingwater pumps or running conveyor belts.

39

![]()

![]()

![]()

|

— Table 4.2 Maximum starting times in seconds for occasional starting, single- speed motors |

— 4.6 Starting limitations Starting time Starting time is a function of load torque, inertia and motor torque. As the starting current is always much higher than the rated current, an excessively long starting period will cause harmful temperature rise in the motor. The high current also causes electromechanical stress on the motor. |

Permitted starting time

In view of temperature rise, the starting time must not exceed the timespecified in the table. The figures in the table apply to starting from normaloperating temperature. When starting from cold, the figures can be doubled.

Number of poles Motor size Starting method 2 4 6 856 DOL 25 40 NA NA63 DOL 25 40 NA NA71 DOL 20 20 40 4080 DOL 15 20 40 4090 DOL 10 20 35 40100 DOL 10 15 30 40112 DOL 20 15 25 50 Y/D 60 45 75 150

132 DOL 15 10 10 60 Y/D 45 30 30 20

160 DOL 15 15 20 20 Y/D 45 45 60 60

180 DOL 15 15 20 20 Y/D 45 45 60 60

200 DOL 15 15 20 20 Y/D 45 45 60 60

225 DOL 15 15 20 20 Y/D 45 45 60 60

250 DOL 15 15 20 20 Y/D 45 45 60 60

280 DOL 15 18 17 15 Y/D 45 54 51 45

315 DOL 15 18 16 12 Y/D 45 54 48 36

355 DOL 15 20 18 30 Y/D 45 60 54 90

400 DOL 15 20 18 30 Y/D 45 60 54 90

450 DOL 15 20 18 30 Y/D 45 60 54 90

—

Table 4.2

40 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Permitted frequency of starting and reversing

When a motor is subjected to frequent starting, it cannot be loaded at itsrated output because of thermal starting losses in the windings.Calculating the permissible output power can be based on the number ofstarts per hour, the moment of inertia of the load, and the speed of theload. Mechanical stresses may also impose a limit below that of thermalfactors.

|

Permitted output power P = |

m P 1− N m o |

P

N = rated output of motor in continuous duty

(JM + J’L)

m = x X

J

m

X = number of starts per hour

JM = moment of inertia of motor in kgm2

J’L = moment of inertia of load in kgm2, recalculated for the motor shaft, i.e. multiplied by (load speed /motor speed)2. The moment

of inertia J (kgm2) equals ¼ GD2 in kpm2.

m

o = highest permitted number of starts per hour for motor at no load,

as stated in the table at right.

Highest permitted number of reversals per hour at no load mr = m0 /4.

41

![]()

![]()

![]()

|

— Table 4.3 Highest permitted number of starts/hour at no load, m 0 |

Number of poles Motor size 2 4 6 8 56 12000 9000 – – 63 A, B 11200 8700 – – 71 A, B 9100 8400 16800 15700 80 A, B 5900 8000 16800 11500 90 L 3500 7000 12200 11500 100 L 2800 – 8400 – |

112 M 1700 6000 9900 16000

132 M 1700 2900 4500 6600

160 ML 650 – – 5000

180 ML 400 1100 – –

200 ML 385 – 1900 –

225 SM – 900 – 2350

250 SM 300 900 1250 2350

280 SM, ML 125 375 500 750

315 SM, ML 75 250 375 500

355 SM, ML, LK 50 175 250 350

400 L, LK 50 175 250 350

450 L On request

—

Table 4.3

42 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

— Table 4.4 Speed constant K1 as a function of frequency and pole pairs. |

Starting characteristics Catalogs usually state the maximum starting time as a function of motor size and speed. However, the standard IEC 60034-12 specifies the permitted moment of inertia of the driven machine instead of starting time. For small motors, the thermal stress is greatest in the stator winding, whereas for larger motors it is greatest in the rotor winding. |

If the torque curves for the motor and the load are known, the startingtime can be calculated with the following equation.

|

TM – TL = (JM + JL) x |

dω dt |

where

TM = motor torque, Nm T

L = load torque, Nm

JM = moment of inertia of the motor, kgm2 JL = moment of inertia of the load, kgm2 ω = angular velocity of the motor

In case of gearing TL and JL will be replaced by T’L and J’L respectively.

If the starting torque TS and maximum torque Tmax of the motor, togetherwith the nature of the load, are known, the approximate starting time can be calculated with the following equation.

(JM + J’L)

tst = x K1

T

acc

where

tst = starting time, s

Tacc = acceleration torque, Nm

f ) where p represents the number of

K1 = speed constant (2ϕ p

pole pairs

|

Speed constant |

Poles 2 4 6 8 10 |

Frequency Hz |

nm 3000 1500 1000 750 600

K

1 314 157 104 78 62 50

n

m 3600 1800 1200 900 720

K

1 377 188 125 94 75 60

—

Table 4.4

43

![]()

![]()

![]()

![]()

![]()

The average value for TM:

TM = 0.45 x (Ts + Tmax)T

acc = TM – KL x TL

KL can be obtained from the table below:

Lift motion Fan Piston pump Flywheel

K

L 1 1/3 0.5 0

Examples from the ABB calculation program on starting time

If there is gearing between the motor and the driven machine, the loadtorque must be recalculated to motor speed with the following formula.

|

T’L = TL x |

n n L M |

The moment of inertia must also be recalculated:

|

J’L = JL x |

n L n M |

2 |

44 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

Examples of starting performance with various load torques 4-pole motor, 160 kW, 1475 r/min

Torque of the motor T

N = 1040 Nm

Ts = 1.7 x 1040 = 1768 NmT

max = 2.8 x 1040 = 2912 Nm Moment of inertia of motor: J

M = 2.5 kgm2 The load is geared down in a ratio of 1:2

Torque of the load

TL = 1600 Nm at nL = nM/2 r/min

T’L = 1600 x 1/2 = 800 Nm at nM r/min

Moment of inertia of the load

JL = 80 kgm2 at nL = nM/2 r/min

J’L = 80 x (½)2 = 20 kgm2 at nM r/min

Total moment of inertia J

M + J’L at nM r/min

2.5 + 20 = 22.5 kgm2

45

![]()

![]()

![]()

![]()

![]()

|

Example 1: TL = 1600 Nm T’ L = 800 Nm Constant during acceleration T T acc = 0.45 x (TS + Tmax) – T’L acc = 0.45 x (1768 + 2912) – 800 = 1306 Nm |

Torque Lift motion |

T’L |

Speed |

(J

M + J’L)

tst = x K1

T

acc

22.5 x 157

tst = = 2.7 s 1306

|

Example 2: T L = 1600 Nm T’L = 800 Nm Linear increase during acceleration T acc = 0.45 x (TS + Tmax) – ½ x T’L Tacc = 0.45 x (1768 + 2912) – ½ x 800 = 1706 Nm |

Piston pump |

Torque |

T’L |

||||||

|

tst = (JM + J’L) x K1/Tacc |

Speed |

||||||||

157

tst = 22.5 x = 2.1 s 1706

|

Example 3: T L = 1600 Nm T’L = 800 Nm Square-law increase during acceleration T T acc = 0.45 x (TS + Tmax) – ⅓ x T’L acc = 0.45 x (1768 + 2912) – ⅓ x 800 = 1839 Nm |

Fan |

Torque |

T’L |

||||||||||||||

|

(JM + J’L) tst = x K1 T acc 22.5 x 157 t st = = 1.9 s 1839 |

Speed |

||||||||||||||||

|

Example 4: TL = 0 T acc = 0.45 x (TS + Tmax) Tacc = 0.45 x (1768 + 2912) = 2106 Nm |

Flywheel |

Torque |

|||||||||||||||

|

(JM + J’L) tst = x K1 T acc 22.5 x 157 tst = = 1.7 s 2106 |

Speed |

||||||||||||||||

46 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

![]()

—

4.7 Duty types

The duty types are indicated by S1…S10 according to IEC 60034-1 andVDE 0530 Part 1. The outputs given in the catalogs are based oncontinuous running duty, S1, with rated output. In the absence of anindication of the rated duty type, continuous running duty is assumedwhen considering motor operation.

|

S1 Continuous running duty Operation on constant load of sufficient duration for thermal equilibrium to be reached. Designation S1. |

P |

N

|

S2 Short-time duty Time shorter than that required to reach thermal equilibrium, followed by a rest and a de-energized period of sufficient duration to allow motor temperature to reach ambient termperature or cooling temperature. 10, 30, 60, and 90 minutes are recommended for the rated duration of the duty cycle. Designation for example S2 60 min. |

P |

N |

Time Time |

||||||||||||||

|

S3 Intermittent duty A sequence of identical duty cycles, each including a period of operation at constant load, a rest and a de-energized period. The duty cycle is too short for thermal equilibrium to be reached. The starting current does not significantly affect temperature rise. Recommended values for the cyclic duration factor are 15, 25, 40, and 60 percent. The duration of one duty cycle is 10 min. Designation for example S3 25 %. |

P |

N R One duty cycle |

Time |

||||||||||||||

|

Cyclic duration factor = |

N N + R |

x 100 % |

|||||||||||||||

Explanation of symbols used in this and the following figures

P = output power F = electrical braking PD = acceleration V = operation of no load

N = full load

N = operation under rated condition R = at rest and de-energized

47

![]()

![]()

![]()

S4 Intermittent duty with starting A sequence of identical

One duty cycle

duty cycles, each cycleincluding a significantperiod of starting,

P

operation at constant load,

D N R Time

a rest and a de-energized

period. The cycle-time is too short for thermal equilibrium to be reached.In this duty type, the motor is brought to rest by the load or by mechanical braking which does not thermally load the motor. Thefollowing parameters are required to fully define the duty type: the cyclicduration factor, the number of duty cycles per hour (c/h), the moment of inertia of the load (JL) and the moment of inertia of the motor (JM).

Designation for example S4 25 % 120 c/h J

L = 0.2 kgm2 JM = 0.1 kgm2.

|

Cyclic duration factor = |

D + N D + N + R |

x 100 % |

S5 Intermittent duty with starting and electrical braking A sequence of identical

One duty cycle

duty cycles, each cycle Pconsisting of a significantstarting period, a period of

operation at constant load,

Time

a period of rapid electric

F braking, a rest and a de-

D N R

energized period. The duty

cycles are too short for thermal equilibrium to be reached. The followingparameters are required to fully define the duty type: the cyclic durationfactor; the number of duty cycles per hour (c/h), the moment of inertia of the load (J

L) and the moment of inertia of the motor (JM).

Designation for example S5 40 % 120 c/h J

L = 2.6 kgm2 JM = 1.3 kgm2.

|

Cyclic duration factor = |

D + N + F D + N + F + R |

x 100 % |

S6 Continuous operation periodic duty

A sequence of identical duty cycles, each cycle consisting of a period atconstant load and a period of operation at no-load. The duty cycles aretoo short for thermal equilibrium to be reached. Recommended valuesfor the cyclic duration factor are 15, 25, 40, and 60 percent. The durationof the duty cycle is 10 min.

|

Designation for example S6 40 %. Cyclic duration factor = 100 % x |

N N + V |

48 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

![]()

![]()

![]()

S7 Continuous operation periodic duty with electrical braking A sequence of identical

P

duty cycles, each cycle

One duty cycle

consisting of a startingperiod, a period of operation at constant load,

Time

and a period of braking.

D N F

The braking method is

electrical braking such as counter-current braking. The duty cycles aretoo short for thermal equilibrium to be reached. The following parameters are required to fully define the duty type: the number of duty

cycles per hour (c/h), the moment of inertia of the load (Jmoment of inertia of the motor (J

L), and the M).

Designation for example S7 500 c/h J

L = 0.08 kgm2 JM = 0.08 kgm2.

S8 Continuous-operation periodic duty with related load speed changes A sequence of identical duty cycles, each cycle

One duty cycle

P

consisting of a startingperiod, a period of operation at constant load

Time corresponding to a

predetermined speed,

D N F1 N2 F2 N3

followed by one or more

periods of operation at other constant loads corresponding to differentspeeds. There is no rest or a de-energized period. The duty cycles are tooshort for thermal equilibrium to be reached. This duty type is used forexample by pole-changing motors. The following parameters are requiredto fully define the duty type: the number of duty cycles per hour (c/h), the moment of inertia of the load (JL), the moment of inertia of the motor (JM),and the load, speed, and cyclic duration factor for every operation speed.

Designation for example S8 30 c/h JL = 63.8 kgm2 JM = 2.2 kgm2.

24 kW 740 r/min 30%60 kW 1460 r/min 30%45 kW 980 r/min 40%

|

Cyclic duration factor 1 = Cyclic duration factor 2 = Cyclic duration factor 3 = |

D + N 1 D + N 1 + F1 + N2 + F2 + N3 F1 + N2 D + N1 + F1 + N2 + F2 + N3 F2 + N3 D + N 1 + F1 + N2 + F2 + N3 |

x 100 % x 100 % x 100 % |

49

S9 Duty with non-periodic load and speed variationsA duty in which, generally, load and speed vary non-periodically withinthe permissible operating range. This duty includes frequently appliedoverloads that may greatly exceed the full loads. For this duty type,suitable full load values should be taken as the basis of the overloadconcept.

S10 Duty with discrete constant loads and speeds A duty consisting of a specific number of discrete values of load (or equivalent loading) and if applicable, speed, each load/speed combination being maintained for sufficient time to allow the machine to reach thermal

equilibrium. The minimum load within a duty cycle may have the valuezero (no-load or de-energized and at rest).

The appropriate designation is S10, followed by the per-unit quantitiesplΔt for the respective load and its duration, and the per-unit quantity TLfor the relative thermal life expectancy of the insulation system. Thereference value for the thermal life expectancy is the thermal lifeexpectancy at rating for continuous running duty and permissible limitsof temperature rise based on duty type S1. For a time de-energized andat rest, the load shall be indicated by the letter r.

Example: S10 plΔt = 1.1/0.4; 1/0.3; 0.9/0.2; r/0.1 TL = 0.6

The value of TL should be rounded to the nearest multiple of 0.05.

For this duty type a constant load appropriately selected and based on duty type S1 shall be taken as the reference value (‘Pref’ in the figure) forthe discrete loads.

Note: The discrete values of load will usually be equivalent loading based on integration over aperiod of time. It is not necessary that each load cycle be exactly the same, only that each loadwithin a cycle be maintained for sufficient time for thermal equilibrium to be reached, and thateach load cycle is capable of being integrated to give the same relative thermal life expectantly.

50 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

— Table 4.5 Permitted output in short time duty S2 as percentage of rated output — Table 4.6 Permitted output in intermittent duty S3 as percentage of rated output |

— 4.8 Uprating Because of the lower temperature rise in the motor in short-time or intermittent duty, it is usually possible to take higher output from the motor in these types of duty than in continuous duty, S1. The tables below show some examples of this. Attention must be paid to the motor’s maximum torque, T max/TN must be >1.8 referred to increased output.

Short-time duty S2 Poles |

30 min 2 105 125 130

4 – 8 110 130 130

60 min 2 – 8 100 110 115

—

Table 4.5

|

Intermittent duty S3 Poles |

Permitted output as % of rated output in S1 continuous duty for motor size 56 – 100 112 – 250 280 – 450 |

15 % 2 115 145 140

4 140 145 140

6, 8 140 140 140

25 % 2 110 130 130

4 130 130 130

6, 8 135 125 130

40 % 2 110 110 120

4 120 110 120

6, 8 125 108 120

60 % 2 105 107 110

4 110 107 110

6, 8 115 105 110

—

Table 4.6

51

—

4.9 Efficiency and types of losses

Efficiency of a motor is a measure of how well it is capable of convertingelectrical energy into mechanical work. Lost energy is emitted in the form ofheat. To increase efficiency, losses have to be reduced.

Motor losses can be divided into five main categories. The first category is ironlosses in the core, the second windage and friction losses. Load losses, whichvary with the load, are classified into copper losses in the stator, rotor losses,and stray load losses. All losses can be influenced by motor design andconstruction solutions.

Constant losses

Iron losses in the core are caused by the energy required to overcome theopposition to changing magnetic fields in the core material. These lossescan be reduced by using better-quality steel and by lengthening the core toreduce magnetic flux density.

Windage and friction losses are caused by air resistance and bearing friction.Improved bearing design and bearing seal selection, air flow and fan designaffect these losses. The fan must be large enough to provide adequate cooling,but not so large as to reduce efficiency and increase noise. To reach an optimalcooling effect in each ABB motor, blade sizes and pitches vary in different fanmodels.

Load losses

Of load losses, stator copper losses (also referred to as I2R losses) are causedby heating from the current flow through the resistance of the stator winding.Techniques for reducing these losses include optimizing the stator slot design.

Rotor losses are depending on the slip. These losses are reduced for example byincreasing the size of the conductive bars and end rings to produce lowerresistance. Stray load losses are the result of leakage fluxes induced by loadcurrents. These can be decreased by improving slot geometry.

Completely new motor designs are also developed to increase efficiencybeyond known limits. The synchronous reluctance motor is an example of thesenew designs.

Efficiency values for rated output are listed in the technical data tables in ABBproduct catalogs.

52 LOW VOLTAGE MOTORS MOTOR GUIDE JULY 2019

—

4.10 Power factor

A motor consumes both active power, which it converts into mechanicalwork, and reactive power, which is needed for magnetization and whichis not converted to work.

The active and reactive power, represented in the diagram (below) by Pand Q, together give the apparent power S. The ratio between activepower, measured in kW, and apparent power, measured in kVA, is knownas the power factor. The angle between P and S is usually designated asϕ, and the power factor itself is designated as cos ϕ.

Power factor is usually between 0.7 and 0.9. It is lower for small motorsand higher for large motors.

Power factor is determined bymeasuring the input power,voltage and current at ratedoutput power. The powerfactor stated is subject to atolerance of (1-cos ϕ)/6 .

If there are many motors in an installation, a lot of reactive power will beconsumed and therefore the power factor will be lower. For this reason,power suppliers sometimes require the power factor of an installation tobe increased. This is done by connecting capacitors to the supply whichabsorb reactive power and thus raise the power factor.

Reactive-power compensation

With phase compensation, the capacitors are usually connected in parallelwith the motor, or with a group of motors. However, in some cases, over-compensation can cause an induction motor to self-excite and run as agenerator. Therefore, to avoid complications, it is a normal practice not tocompensate for more than the no-load current of the motor.

The capacitors must not be connected in parallel with single phases ofthe winding; such an arrangement may make the motor difficult orimpossible to start with star-delta starting.

If a two-speed motor with separate windings has phase compensationon both windings, the capacitors should not remain in circuit on theunused winding.

53

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

|

— Table 4.7 Phase compensation |

Under certain circumstances, such capacitors can cause increased heating of the winding and possibly also vibration. |

Constant K cos ϕ Compensation to cos ϕ = without compensation 0.95 0.90 0.85 0.80 0.50 1.403 1.248 1.112 0.982 0.51 1.358 1.202 1.067 0.936 |

||||

|

The following formula is used to calculate the size (per phase) of a capacitor for a mains frequency of 50 Hz: |

0.52 1.314 1.158 1.023 0.892 0.53 1.271 1.116 0.980 0.850 0.54 1.230 1.074 0.939 0.808 0.55 1.190 1.034 0.898 0.768 0.56 1.150 0.995 0.859 0.729 |

|||||

|

C = 3.2 · 106 · |

Q U 2 |

0.57 1.113 0.957 0.822 0.691 0.58 1.076 0.920 0.785 0.654 0.59 1.040 0.884 0.748 0.618 |

||||

|