|

Part 1 Status |

Document Version |

||||||

|

1st Issue 1.0 |

||||||||

|

Logistics guideline BR-packaging manual |

Author BR/PUR-LOG |

Date 2006 |

||||||

Contents

1. Aim …………………………………………………………………………………………………………2

2. Scope ……………………………………………………………………………………………………..2

3. Term definitions ………………………………………………………………………………………2

4. Regulations, guidelines, standards and legislations………………………………….3

5. Packaging at Bosch Rexroth…………………………………………………………………….3 5.1 General information on functions and usages of packaging………………………….3 5.2 Accessories …………………………………………………………………………………………..5 5.3 Reusable packaging……………………………………………………………………………….5 5.3.1 Standard packaging…………………………………………………………………………6 5.3.2 Customer packaging………………………………………………………………………..8 5.4 One way packaging………………………………………………………………………………..8 5.4.1 Standard packaging (transport packaging made of corrugated cardboard)8 5.4.2 Specific packaging…………………………………………………………………………..9 5.5 Display packaging ………………………………………………………………………………..18

6. Unit loads of reusable and one-way packaging ……………………………………….18

7. Information on environment and quality………………………………………………….20 7.1 Hazardous cargo ………………………………………………………………………………….20 7.2 Special requirements for wooden packaging materials ………………………………22 7.3 Regulations on the use of materials ………………………………………………………..23

8. Corrosion prevention……………………………………………………………………………..23

9. Labelling regulations……………………………………………………………………………..25

10. Labelling and marking……………………………………………………………………………26

11. Return and disposal of the packaging …………………………………………………….28

12. Quality standards…………………………………………………………………………………..29

13. Guarantee bond……………………………………………………………………………………..29

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

1. Aim

The logistics guideline packaging manual is intended to inform about the use ofpackaging. It is aiming at pointing out to the persons/ authorities in charge how to package the goods in the most secure and best way.

At the same time it is:

• A support for purchasers in order to demonstrate to suppliers (e.g. in

emerging markets) the use of correct packaging for supplies to BR,

• A teaching aid for BR dispatch departments in order to train associates.

2. Scope

This packaging manual is a recommendation for the Bosch Rexroth AG and itsdifferent subsidiaries. If there are specific laws to observe in a country, thispackaging manual must be sensibly used. Holding companies are recommended toadopt this manual.

However, the application of this logistics guideline is not mandatory. As far as it was possible, further support/ addresses are indicated in the following. BR/PUR-LOG especially points out that the contents of the said guideline do not exempt the persons/ authorities in charge from liability for damage, e.g. for defective packagingor insufficient corrosion protection. The person/ authority in charge is also not exempt from the duty of information about the applicable regulations for packaging and means of packaging.

3. Term definitions

Term definitions are to be found in part 2 of the ZN 02101 “Labelling regulations forpackaging”.

2

|

Part 1 Status |

Document- Version |

||||||

|

1st Issue 1.0 |

||||||||

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

||||||

4. Regulations, guidelines, standards and legislations

Regulations, guidelines, standards and legislations about packaging can be found inthe “Logistics manual for suppliers of the Bosch Group”.

The applicable import regulations for packaging/ packaging materials are containedin the “International Standard for Phyotsanitary Measures No 15” (ISPM).(http://www.fao.org/Legal/treaties/004s-e.htm)

For applicable information on wood packaging see http://www.hpe.de

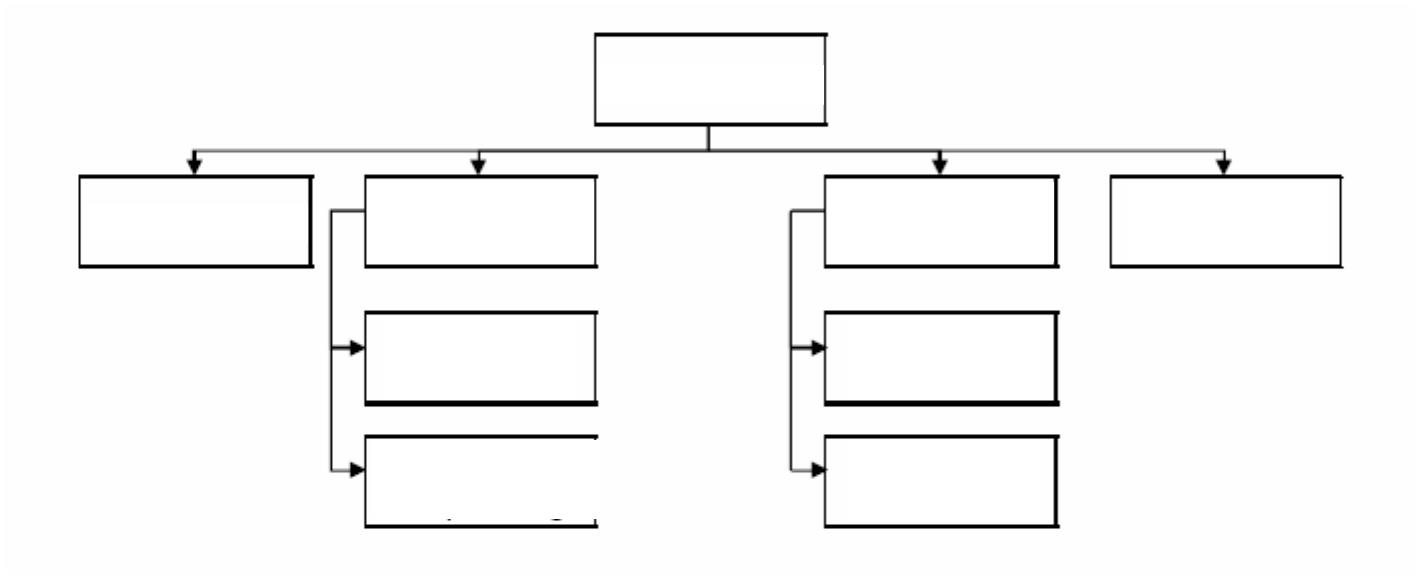

5. Packaging at Bosch Rexroth

Packaging

|

Accessories Reusable packaging |

One-way packaging |

Display packaging |

||||||||

|

Standard packaging |

Standard packaging |

|||||||||

|

Customer packaging |

Specific packaging |

|||||||||

5.1 General information on functions and usages of packaging

Functions of packaging

The most important functions of packaging are the protective function, storingfunction, and the loading and transporting function.

The protective function ensures that the products are protected from mechanical andenvironmental influences and from loss of content.

3

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

The storing function of packaging guarantees that the packaging is designed in such away that the product can be simply, neatly and securely stored.

The loading and transporting function of a packaging ensures that the packaging canusually be easily, efficiently and securely moved.

Usages of packaging

The design and construction of the means of packaging and the inner attachment of the packaged goods must be carried out taking into consideration the (static and dynamic) load during transport, handling, and storing as well as the economic efficiency. The goods must usually be dispatched packaged according to its nature.

Packaging of sea cargo

The shipping units are suitable for sea cargo, i.e. they are space-saving consideringan favourable size/ weight ratio. The most suitable packaging must be chosen each time. The intactness of the goods considering the risks of transport must be guaranteed with regards to outer mechanical and climatic influences as well as corrosion during transport by sea and the following transport until arrival at the destination, by rail, by truck, by inland waterways, by combined transport, during several transfers and longer storages outside.

The design of the packaging must be such that it is suitable for loading by crane aswell as loading by floor trucks. Sizes and weight must be tailored sensibly to loadingspace and load-carrying capacity of the means of transport and the lifting gears.

Packaging of air-cargo

Unless differently stated in an agreement, for transport of air cargo low-weight andspace-saving packaging must be used that still ensures the intactness of the goods regarding outer mechanical and climatic influences as well as corrosion even during post-transport and post-storage.

4

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

Lists of cargo units

In international logistics, a cargo unit is the smallest unit of a consignment of goods.A list of cargo units lists the cargo units on the delivery note.

Usually, the service providers and recipients receive a list of cargo units in additionto the regulations for proper packaging processing. This form of lists of cargo units ismandatory for the processing of a commission.

5.2 Accessories

The accessories are divided into five groups according to their nature andapplication.

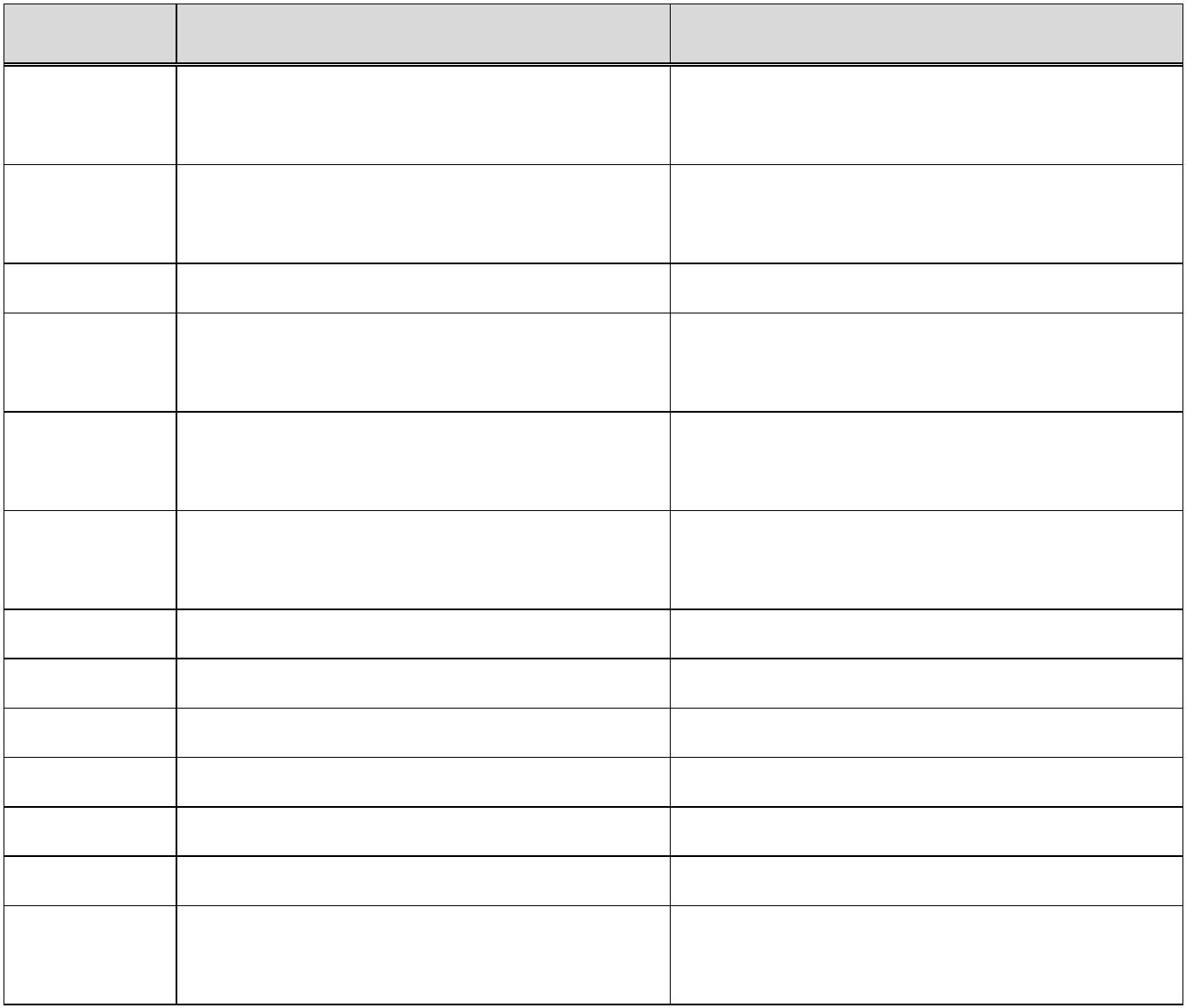

Group Example Note

Plastic PE bags and pouches Reusable (no plastic pouches)

Adhesive Labels Residue-free removal

|

Filling material Padpac |

No styrofoam or filling material made of foodstuff(e.g. maize chips), no packaging foam |

Strapping material Steel/ plastic strap

Anti-tarnish paper VCI–paper Notes under point 8

5.3 Reusable packaging

Reusable packaging can be used several times and is usually used on a lend-returnbasis or is lent against payment of a deposit.

5

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

5.3.1 Standard packaging

European exchange pallet

(euro pallet)

European exchange pallets must be used in the internationally recognized sizes of1200 x 800 mm (euro pallet as per DIN 15146-part 2) and 1200 x 1000 mm(industrial pallet as per DIN 15141-part 4). Only in these cases is a optimum moduleformation (as per DIN 55 520) and full utilization of the pallet guaranteed.Mesh boxpallets

The also exchangeable mesh boxpallets (as per DIN 15155) have the basic size of1200 x 800 mm and thus enable an optimum stackability.

The flat and mesh box-pallets should meet the quality requirements of the „European Pallet Association (EPAL)“.

Small load carriers (KLT, Kleinladungsträger)

The KLT system is a uniform and modular system that can be mechanically andmanually operated. It is standardized to the basic size of 1200 x 800 (Euro) and 1200x 1000 (ISO) and is an exchangeable system that is universally used.

6

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

KLT – types used at Bosch Rexroth:

Characteristic VDA-C-KLT* VDA-R-KLT VDA-RL-KLT VDA-F-KLT

Picture

KLT-design double-walled one-walled one-walled one-walled

Rigid/ foldable rigid rigid rigid foldableFilling weight up to 50 kg up to 20 kg up to 20 kg up to 20 kg

Bottom compatible

compatible compatible

bottom bottom

bottom smooth bottom

* preferred type by Bosch Rexroth: VDA-C-KLT

Stackability

C-KLT 6428 module 600×400 Column ability to be stacked RL-KLT with four-way flat pallet made of

wood, locking plate

The security during transport is only guaranteed if the container system is securedform within, i.e. the KLT are offset stacked. Otherwise, it is recommended to strapthe KLT column.

7

|

Part 1 Status |

Document- Version |

||||||

|

1st Issue 1.0 |

||||||||

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

||||||

5.3.2 Customer packaging

Should the customers of Bosch Rexroth have special requirements for the usage of packaging materials, these must be observed and carried out. In addition, the packaging materials (e.g. the Volvo pallet) that are put at disposal by the customer must be used.

5.4 One way packaging

One way packaging is generally only used for one single transport and are not filledagain.

5.4.1 Standard packaging (transport packaging made of corrugated cardboard)

For transport packaging made of corrugated cardboard, standard sizes marked withan “S” are specified with certain qualities.

There is a modular system of which the basic sizes are such that the packaging canbe stacked in a sea container.

|

Mat. No. |

Inner measures in mm |

Outer measures in mm Quality model: |

Additional creasing for height in mm |

S70 1100x730x940 1130x760x1000 2.96 BAA Fefco 0201 750, 850

S60 1100x730x590 1130x760x650 2.96 BAA Fefco 0201 550, 350

S50 745x550x468 760x565x500 2.91 BC Fefco 0201 250, 350

S55 745x267x218 760x282x250 2.91 BC Fefco 0201 –

S40 535x350x436 550x365x468 2.91 BC Fefco 0201 350

S30 350x260x202 365x275x234 2.70 BC Fefco 0201 150

S20 260x167x202 275x182x234 2.70 BC Fefco 0201 –

S15 172x127x212 182x137x234 1.40 C Automatic bottom Fefco 0711 –

S10 172x127x95 182x137x117 1.40 C Automatic bottom Fefco 0711 –

In addition, only in a few cases there is special packaging, which is generally tailoredto certain products. These are marked with an “X”.

8

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

5.4.2 Specific packaging

The wood thickness of boxes, crates and carriages must be adjusted to the weight, the sensitivity, the position of the gravity centre, and the value of the goods as wellas to the expected effects of transport, handling and storage.

For import and export consignments, one way pallets should be used.

1. Bundling

Type of equipment

Equipment that is not subject to damage by corrosion or mechanical effects, e.g.pipes, pipelines, structural steel, steel constructions.

Construction

The bundling must be done:

• with scantling clasps and locking screws;

• With intermediate layers (threaded onto locking screw poles) made of boards trimmed in parallel depending on the weight of the goods.• The bottom pipe layer must be wedged outside.

• In between the salient screw heads, a batten must be nailed.• The screws must be secured.

• If there is the danger of individual parts sliding out, the relevant securing

measures are to be taken (flat iron or sheets).

• In individual cases, bundling with steel straps or wires must be agreed upon

with the customer depending on the requirements.

|

Upper radial bearing Intermediate layer |

Secured screws |

C- Profile

Marking twoat the side

Intermediate layers

Bundling Bundling with U-iron

9

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

2. Carriages, scantling constructions, boardings

Type of equipment

Bulky equipment and container, heavy cargo units which are not endangered bymechanical or corrosive influences.

Construction

• The construction can either be made of wood or metal. • The packing units have to be fixed on the carriage with steel straps that are lined with elastics , non-skid and screwed onto the carriage with locking screws.

• Flange openings must be closed with sealing and blank flanges or closed with

a cover if necessary.

• Constructions of carriages must not exceed the length and width of the

measures of the goods (B = DA).

• Containers and equipment with their own standing devices must be fitted with

a strong wooden base as anti-skid measure.

Steel straps for

Fixing the woodencorbels

Scan

Intermediate layer ofartificial rubber

|

Full length threaded free rods |

Connecting pieces are to be turned into the blind spot if possible in order to avoid damage and save |

Carriages, scantling constructions, boardings

3. Crates

Type of equipment

Equipment, devices and containers sensitive to corrosion that cannot be packed oncarriages, ladders, parts of stages and platforms, pre-fabricated pipelines as well asmoulded parts with small measures.

10

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

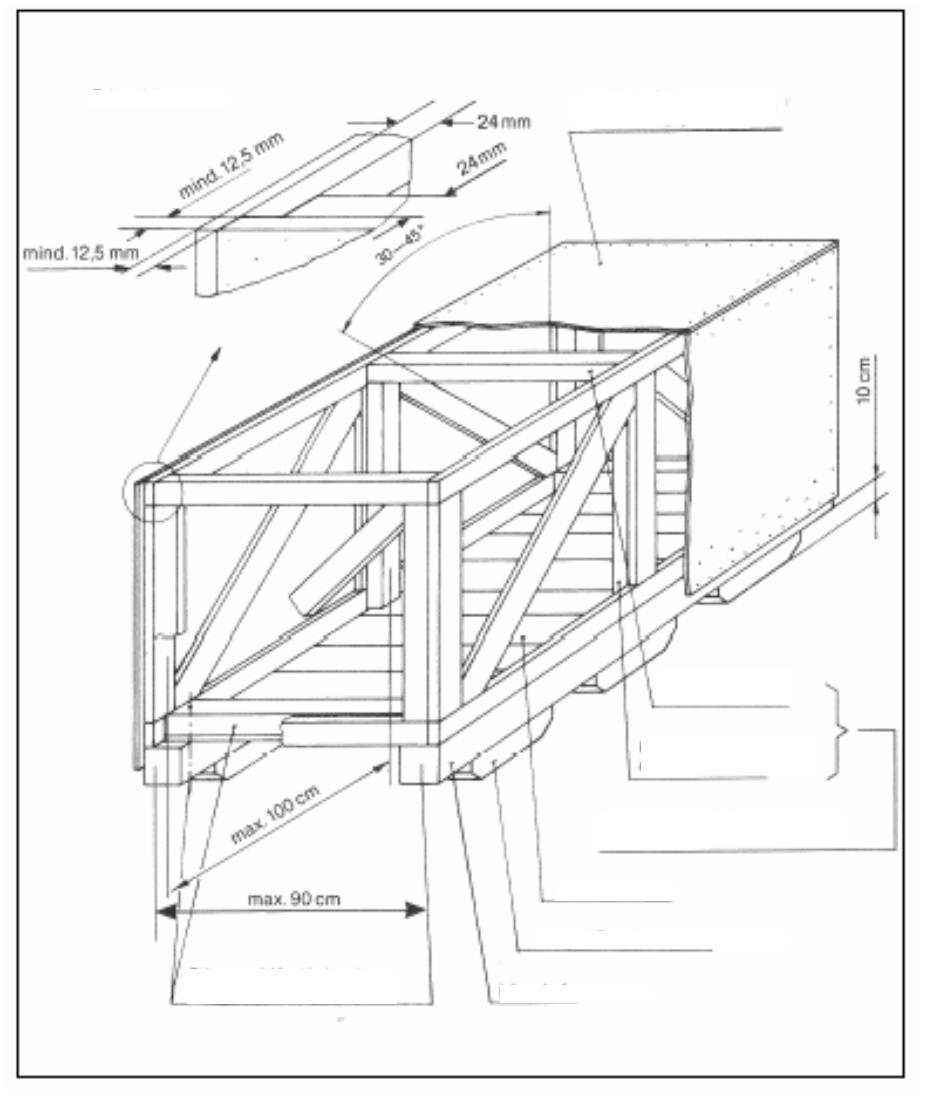

Construction

Bottom

• Longitudinal bottom runners, especially for shipments to the states of the CIS

and for container shipments, or lateral runners

• Maximum distance between longitudinal runners 90 cm (runner-centre to

runner-centre)

• Bottom planks cross-nailed

Side walls:

• Boarding of the side walls vertical, horizontal only if sensible; battens must be

inside

• Distance between the boards not larger than the average board width

Cover:

• Longitudinal boards above the front and side parts recede by 5 mm; lateral

battens, compression wood of cover runs lateral and is supported at the bottom-

side

• Board width 10 – 18 cm

The equipment must be securely fixed at the bottom with full-length bolts possiblythrough the longitudinal runners or be wedged in such a way that they cannot comeout of the packaging. If parts are sensitive to rainwater and/ or soiling, the cover mustbe made of plastic sheet.

If there is the danger of individual parts coming out of the packing unit, it must befully boarded at the front side. The labelling must be fixed on the plywood orchipboard of the cargo units at the specified places. The layout of the runners andbottom runners is to be taken from the sketch.

11

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

Fishplate frame

Minimum 24 mm

Minimum 24 mm

Longitudinal /leteral bottom runner

Front wall scantling bolted withlongitudinal runner

From 500 Kg onwards

Crates

12

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

4. Box with lining

Type of equipment

Equipment that is sensible to mechanical damage, subject to the risk of theft or loss,pipes, pipe bends, flanges, fittings, tools, installation material

Construction

Same construction as crates but fully boarded; side walls must be lined withwaterproof bituminized paper with fabric insert or construction foils (UV-resistant) inbetween the fishplate frame and the boarding. The cover construction must bewatertight and prevent the possible formation of a water pocket. From 500 kgonwards, longitudinal runners must be bolted with the front scantlings. For theventilation of the box, the bituminized paper must be left out at same places in theangle which is created by a diagonal board and the fishplate frame.

Box walls lined with double tar paper

Fishplate frame

Minimum 24 mm

Minimum 24 mm

Longitudinal /leteralbottom runner

Front wall scantling boltedwith longitudinal runner

From 500 Kgonwards

Box with lining

13

|

Part 1 Status |

Document- Version |

||||||

|

1st Issue 1.0 |

||||||||

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

||||||

5. Boxes with alternative surface materials

Plywood box

Boxes made of 5-layer waterproof glued plywood with a minimum thickness of 12.5 mm. The frame construction must have a minimum thickness of 24 mm and must be designed according to the weight and the specific characteristics of the goods to be packaged. The lateral boards must be bolted with the longitudinal runners, the compression wood of covers however, laterally. For the construction of the side andcover parts, the diagonal boards are only to be provided if needed. If the coverconsists of several sheets, the stacks must be sealed with permanently elasticcement or a watertight board must be mounted.

The construction needs the approval of the customer.

|

Edge connection |

Plywood sheets nailed/Dotted |

Compression woodof cover

Support for compressionwood of cover

Both woods nailed with frameconstruction

Bottom boards

Longitudinal / lateral bottom runner

|

Front wall scantling bolted with longitudinal runner |

Longitudinal runner |

Plywood box

14

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

6. Corrugated cardboard box for the shipment in containers of land and air cargo

Type of equipment

Automotive aggregates, spare parts, electrical and electronic parts, homogenousmaterials

Construction

The corrugated cardboard box must be of tested water-resistant corrugatedcardboard as per DIN 55 468 and a one-way flat wooden pallet. 2- and 3-foldcorrugated cardboards of at least the quality class 2.92 – 2.96 are to be used. Thecorrugated cardboard box must be folded and protected from corrosion according tothe requirements of the customer.

The construction needs the approval of the customer.

7. Combination box made of corrugated cardboard

Box made of a wooden frame construction according to the construction of cratesusing 3-fold corrugated heavy cardboard. It should be water-resistant and glued asper DIN 55 468 and correspond at least to the quality classes 2.95 – 2.96.

The construction needs the approval of the customer.

8. Box with polyfoil insulation layer

Type of equipment

Sensitive mechanical equipment, simple electrical equipment, insulating material,fireproof material, packaging period up to 12 months

Construction

The conservation is done by shrink-wrapping in polyfoil using drying agents and, if necessary, corrosion prevention agents. The design of the boxes must allow goodventilation. Otherwise the box must be design like a box with lining. The box must beadditionally labelled with “Packing unit contains drying agent”.

9. Box with insulation layer of aluminium multi-layer foil

Type of equipment

Electrical equipment such as switch cabinets, electric motors, sensitive mechanicalequipment: packaging period more than 12 months

15

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

Construction

The construction is the same as for boxes with lining.

The conservation is done by shrink-wrapping in multi-layer aluminium foil usingdrying agents. The indicators built into the insulation layer on request must be legiblefrom the outside. The openings must be closed with tiltable ventilation shutter.

The box must be additionally labelled with “Packing unit contains drying agent”.

box with lining

At the front or side, a window mustdisplay a hygrometer

Material of insulation layerSeam seal-welded

Drying agent corresponding to foilsurface and regulations by themanufactures

Box with insulation layer of polyfoil/ aluminium multi-layer foil

10.Double box

Type of equipment

Goods that are especially sensitive to impact, shock or vibration, e.g. special electrical or electrostatical equipment, computer, switch cabinets, laboratoryinstruments

Construction

The construction of the box is the same as for a box with lining; in addition, it containsfloating packaging and padding according to weight and sensitivity. The conservationis done by shrink-wrapping in aluminium multi-layer foil using drying agents.

16

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

The construction must be agreed upon by the customer.

The inner box is to be made of plywood or an equivalent material. The materialthickness is 8-12 mm, depending on the weight of the product to be packaged. Theinner clasps and the frame battens must be dimensioned in such a way that full stability of the inner box is ensured and deformation is not possible.

11.Cable reels

Type of equipment

Cable reels, larger than 1m³

Construction

Generally, only new or as good as new cable reels (KTG standard) are to be used. Boarding of the cable reel using 20 mm boards with additional 2-fold steel strapping,nailed and previously carefully conserved cable ends.

12.Built-in packaging

It is characteristic of built-in packaging that various packaging materials are attachedwithout bearing load in order to mechanically protect the actual product.

Type of equipment

Modules and system components whose nature ensures static stability.

Construction

The built-in packaging must be designed is such a way that it can be securelytransported when the packaged product is hoisted. The packaging must be designed with devices (extension sleeves) for transport by floor trucks and with attaching devices that allow for attaching lifting tackles (shackles, ropes, side arms).

13.Transport bottoms

Type of equipment

All materials that are shipped in containers until they reach their final destination

17

|

Part 1 Status |

Document- Version |

||||||

|

1st Issue 1.0 |

||||||||

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

||||||

Construction

Bottom

• Longitudinal runners, on the inside at the head front-wall scantlings that are

bolted with the runners

• Maximum distance between longitudinal runners 90 cm (runner-centre to

runner-centre)

• Bottom is fully boarded

• Lifting eye nut fixed in longitudinal direction and/ or steel-rope strops to pull

the bottom out of the container

• The conservation is done by shrink-wrapping in aluminium multi-layer foil

using drying agents

5.5 Display packaging

Display packaging see part 3 of the packaging manual. (ZN 02102)

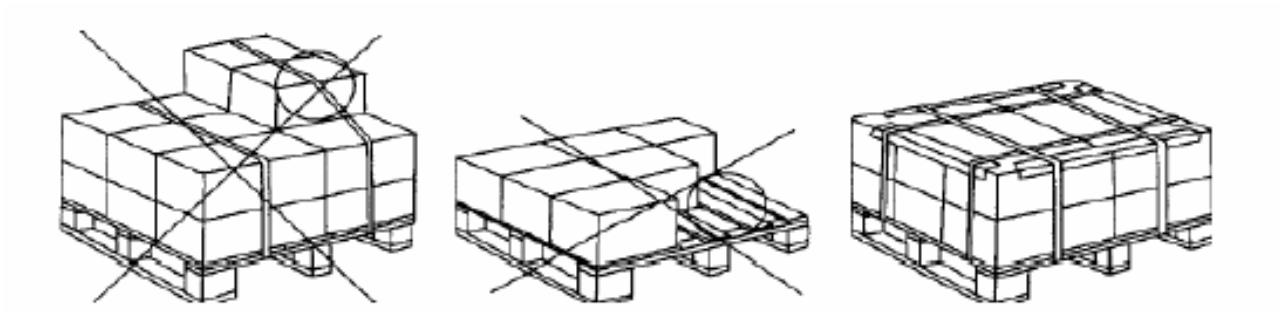

6. Unit loads of reusable and one-way packaging

A unit load is a load that is put together in such a way that the items or packages canbe handled, transported, stacked and stored as a unit.

If the unit load comprises of smaller containers (special or universal containers, KTL orone-way packaging), these must comply with the standard measures of the pallet.

Ability of unit loads to be stacked

Wrong Correct

18

|

Part 1 Status |

Document- Version |

||||||

|

1st Issue 1.0 |

||||||||

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

||||||

Wrong Wrong Correct

Formation of unit loads

The basic size of the unit loads (1200 x 800 mm or 1200 x 1000 mm) must not beexceeded by the goods and unit loads. The height of the entire unit load must not exceed 1000 mm.

The unit load must be transportable by floor trucks and automated vehicle systems. Thus, the space in between the pallet feet must not be taken up by the securing devices of the unit load. Unit loads must be secured in such a way that the transport packaging cannot get out of place during transport. This can be ensured by using: • Shrink hoods

• Plastic elastic straps

• Shrink foils

Straps cutting into the cardboard packaging are not permissible. This can be avoidedby using edge protectors.

If something is taken out of the unit load, it must be ensured that the rest is stable.

Wrong Correct

19

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

7. Information on environment and quality

7.1 Hazardous cargo

Hazardous cargo is material that poses a risk for humans, animals, or the publicsafety and order when transported on public means of transport (road, rail,waterways, air traffic).

Guidelines for hazardous cargo

Means of transport RegulationRoad traffic ADR/ GGVSRail traffic RID

Ocean shipping IMDG-Code

Air traffic ICA-TI or IATA-DGR-manual

Basically, hazardous goods must not be packaged as sub package. The regulationson hazardous cargo must be strictly observed.

The materials to be delivered can only be filled into tested inner packaging (casks,buckets, other containers). For all regulations, specific packaging requirements, filling materials and bans on joint transportation must be observed.

In order to identify a substance, solution or an item with hazardous characteristics asper the regulations on the transportation of hazardous cargo or to determine theconditions for a transportation (e.g. shipping ban, exemptions, means of shipping), they must be classified.

They are classified by the substance characteristics which are, for example, stated inthe manufacturer’s security data sheets.

Classification

Substances are classified according to the following system:

• UN number

• Hazard class

• Packaging group• Classification code

20

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

UN number

Substances, solutions or mixtures are assigned with a four-digit number worldwidethat is allocated by the UNO.

Hazard class

All hazardous goods are classified into hazard classes according to theircharacteristics. The classes indicate the main possible hazards (e.g. inflammable,toxic or radioactive)

List of the hazard classes

Class Designation Examples

1 Explosive substances and items with explosives not relevant*

2 Gases Spray cans, acetylene, oxygen, nitrogen

3 Inflammable liquid substances Paint, solvents, fuel, alcohol

4.1 Inflammable liquid substances Oil and solvent-containing waste, paint filter

4.2 Self-igniting substances Coal dust, soiled machine cleaning cloths

4.3 Substances that develop inflammable

gases when in contact with water Calcium-carbide

5.1 Substances causing inflammation Hydrogen peroxide

5.2 Organic peroxides Curing agents, adhesives

6.1 Toxic substances Cyanide, isocyanate

6.2 Infectious substances not relevant7 Radioactive substances Ionization detectors

8 Caustic substances Acids, bases, accumulators

9 Various hazardous substances and

items Asbestos, PCB-capacitors, special oils

*generally not available at Bosch Rexroth

21

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

Packaging group

Besides the classification in hazard classes, the largest part of the hazardous goodsis also classified in so-called packaging groups I, II, and III.

Degree of Danger

|

Packaging group I (X) For substances with great hazard (very hazardous substances) |

Packaging group II (Y) For substances with medium hazard (hazardous substances) |

Packaging group III (Z) For substances with medium hazard (less hazardous substances) |

(X, Y, Z letters of efficiency of the packaging)

Classification code

In order to specifically define the hazard arising from a substance, each substance receives an additional classification letter besides the already described classification.

7.2 Special requirements for wooden packaging materials

In the international trade with packaging material made of solid wood, the hytohygienic regulations of the IPPC (International Plant Protection Convention), a sub-organization of the FOA (Food and Agriculture Organization of the UN) must be observed. These regulations stipulate treatment with recognized processes which comprise of heat treatment of at least 30 minutes with a core temperature of 56°Cand disinfection with methyl bromide. The packaging must be marked clearly with a corresponding label with an identification code which consists of the ISO country code, the regional code and a four-digit identification number.

The phytosanitary services or offices inform for which countries, from what time andto what extent the IPPC-standard applies.

For applicable information on wood packaging see http://www.hpe.de

22

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

7.3 Regulations on the use of materials

Type Recommendation – alternative Materials to be avoided

|

Cardboards Free of materials harmful to paper production |

with water-insoluble coating or adhesives |

Composites not recommended

Wood Untreated solid wood or plywood Chipboards, coated or varnished wood, wood wool

Plastics PE, PP, PUR PVC, PC, styrofoam chips

|

Anti-tarnish paper |

VCI paper, which is proven to be reusable together with paper/cardboard |

Incompatibly impregnated or soaked paper (e.g. bituminized, oiled and waxed paper) |

Banned materials

The cumulative concentration of lead, cadmium, mercury, and chromium (VI) inpackaging materials must not exceed the maximum permissible value of 100 ppm asdefined in the EU directive on packaging (94/62/EG).

[Bosch Rexroth, ZN 07950-01]

In addition, ZN 07950-12 is applicable for VCI-packaging (volatile corrosioninhibitors).

A detailed list of declarable and banned substances is to be found in the BoschRexroth ZN 07950- 12.

8. Corrosion prevention

Corrosion is the attack on and destruction of metallic materials by chemical orelectrochemical reactions with active substances of the environment. Corrosivematters are those substances surrounding the part, affecting the material andcausing corrosion.

Conservation

Conservation must provide a temporarily restricted protection against detrimental influences and thus preserve the state at the time the conservation was carried out.

23

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

Only anti-corrosion agents that are approved by the department processengineering, environmental protection and industrial safety can be used.

Type, nature and time of the inner and outer conservation of parts, devices andequipment made of iron materials depend on

• the subsequent treatment,

• the subsequent application purpose,

• the sensitivity of technical surfaces to corrosion and other detrimental

influences (dust, soiling etc)

• the storage conditions and duration,

• the technical terms of delivery of the customer.

Anti-corrosion measures for individual parts

Anti-corrosion measures for individual parts are already carried out in themanufacturing stage (e.g. by using corrosion-inhibiting coolant – and lubricantadditives during the processing). If this temporarily restricted protection (due to longthrough-put times of the parts) does not provide sufficient conservation, this will beachieved by using VCI paper, dewatering fluid or anti-corrosion oil. The VCI paper(Volatile Corrosion Inhibitor) is an inhibitor which inhibits or prevents chemical reactions.

Usually, the corrosion protection is carried out with a primer coat on all outersurfaces of the device excluding lands (AB 01- 03.05). Parts that are immediately assembled after manufacturing without any interim storage do not need to be conserved.

Parts that are especially sensitive to corrosion or are subject to long storage periods(e.g. stock parts) must be additionally protected with an anticorrosive paper with VCIactive substance or by shrink-wrapping and evaluation or shrink-fitting in water-vapourtight plastic foils. Parts that have a reduced protection after a certain storage period according to experience are treated with a subsequent conservation as a means ofprevention.

Abraded surfaces

Abraded surfaces (lands) of devices receive caps of special cardboard or plastic withVCI active substance for protection.

Safety measures for aggregates

Aggregates are order-specific, complete equipment and are thus subject to inner andouter conservation after completion and final testing in accordance with order specifications and the customer regulations.

24

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

Machines, switch-gear assemblies, electrical devices and all goods exposed tocorrosion must be shrink-wrapped in a largely water-vapour tight insulation layeradding drying agents for a conservation period of at least 12 months. Materials for theinsulation layer are polyethylene foil and aluminium multi-layer foil. The foils must becarefully and tightly sealed in order to create watertight or nearly water-vapour tightinsulation layers. The air within the insulation foil must be sucked off until theinsulation layer clings on to the product that needs to be protected. After testing thetightness, the insulation layer must be draped around the packing unit so that theremaining air can circulate within the insulation layer. The insulation layers must beprotected against pressure and abrasion from the inside and outside with suitable non-hygroscopic cushioning material.

Drying agent

The aim of using a drying agent is to create a closed system in which the relative airhumidity is reduced to less than 40% for the entire period of transport, handling andstorage since in this range no condensation takes place anymore.

The drying agent binds the water and reduces the relative air humidity to a targetedvalue.

The necessary number of drying agent units is calculated as per DIN 55474. Thedrying agents can be purchased with 1/6, 1/3, ½, 1, 2, 4, 8, 16 or 32 units.

The drying agents must be placed in the upper part of the climate package so that they get sufficient air. Direct contact of the drying agents with the products mustalways be avoided as the moist drying agent would only create corrosion. In addition,it is sensible to use several smaller sachets of drying agent instead of few larger ones as the surface of the available drying agents expands in order to absorb the water.

9. Labelling regulations

Bar-coded label

The shipping pallets are labelled with one address sticker with bar code.The place of the sticker must be clearly visible, right- and angular adjusted. Thedistance should be 100 mm (+/- 50 mm) to the top of the pallet and to the lateraledge.

25

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

Central standard

The central standard “labelling regulations packaging” (ZN 02101), are describedspecifications for Bosch Rexroth (see part 2 of the packaging manual).

10. Labelling and marking

Labelling of individual parts

All individual parts, even loose parts within a cargo unit must be separately labelled.This labelling must be mentioned in the list of cargo units/ delivery note. Thecontractor will be notified of our individual labelling along with our order or ourguidelines for the shipping procedure respectively.

Marking of the packing units

The packing units must either be marked with a sea watertight light-resistantcontrasting colour with the help of a stencil or with marking labels that are providedby the customer. If the packing unit is marked with a stencil, the size of the letteringdepends on the measures of the package. Unpackaged parts and carriages must bemarked directly on the packing unit or on a plywood sheet. All packing units must bemarked on both longitudinal sides.

Marking regulations are created with reference to the order and are provided to thecontractor in time.

26

|

Part 1 Status |

Document- Version |

||||||

|

1st Issue 1.0 |

||||||||

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

||||||

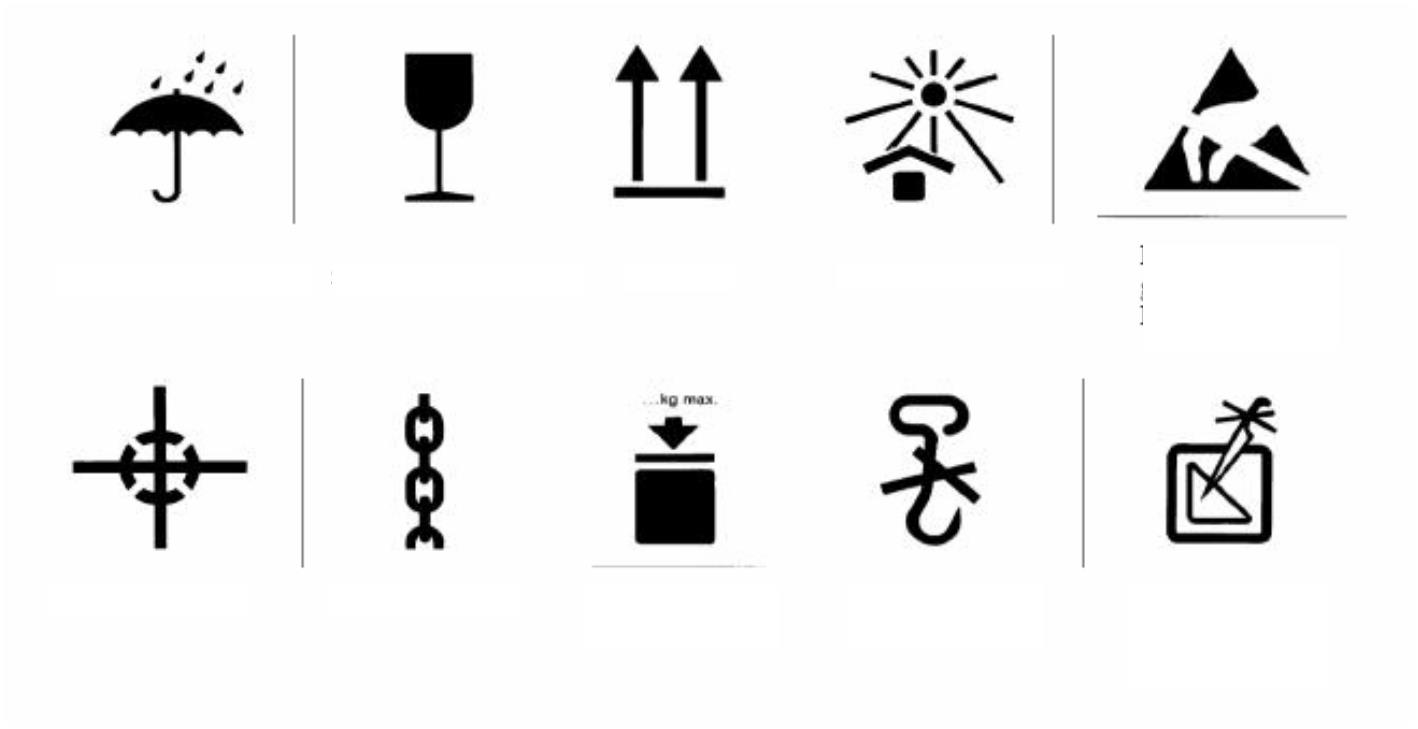

Handling symbols

For the labelling of goods which must be handled in a particular way, internationalsymbols as per DIN 55 402 must be attached.

Protect from moisture Fragile material Up Protect from heat Electro statically risky component

|

Centre of gravity Fasten here Permitted stack load |

Hand hook prohibited |

Do not damage insulating layer |

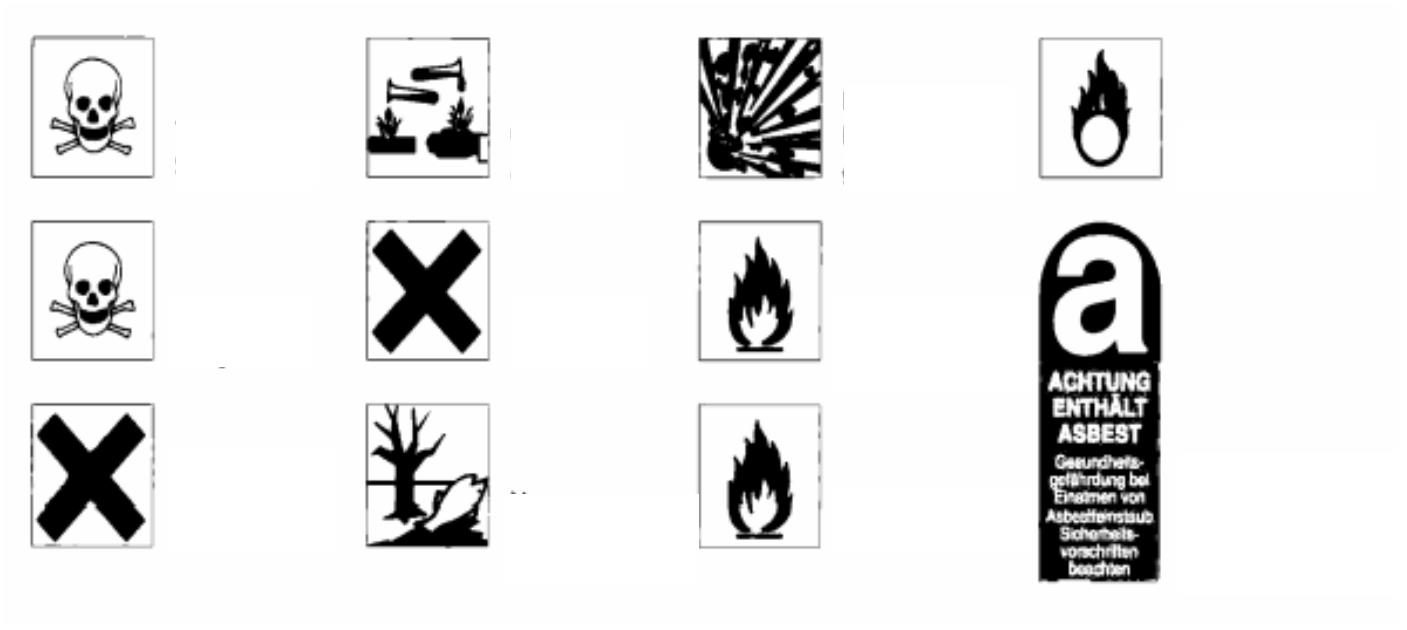

Symbols for hazardous cargo

The symbols for hazardous cargo are to be taken from the international code forhazardous cargo. The labelling is done according to the valid codes.

|

T+ Very toxic |

C Caustic |

E Explosive O Oxidising |

|||||||||||||

|

T Toxic |

Xi Irritant |

F+ Highly flammable |

|||||||||||||

|

Xn Noxious N Environmentally hazardous |

f Flammable |

Formulations and products containing asbestos |

|||||||||||||

27

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

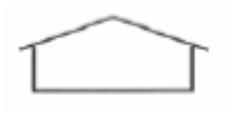

Storage symbols

The following storage labels can be used unless order-related storage symbols arespecified.

|

Open-air ground Covered warehouse |

Closed warehouse |

Closed, heated warehouse, minimum temperature +8° C |

Closed, heated, air-conditioned warehouse, minimum temperature +8° C, maximum air humidity 65% |

11. Return and disposal of the packaging

Basically, it is recommended to use re-usable packaging.

Return

The customer reserves the right to inspect the packaging at a sub-supplier without any warning. In the case of an announced inspection, the packaging must not besealed so that the inner packaging can be checked. The positive inspection does notrelease the contractor from his duty to package the products duly and properly.

Disposal

One way packaging

The disposal of one-way packaging is part of the concluded supply agreement.

Reusable packaging:

It is recommended to use only absolutely functional re-usable packaging. If this is not the case, it must be exchanged. In addition, it is advisable to use only cleanpackaging.

The re-usable packaging must be administered in an inventory. The return of theempties is carried out via the pool for re-usable packaging.

28

|

Part 1 Status |

Document- Version |

1st Issue

1.0

|

Logistics Guideline BR-Packaging Manual |

Author BR/PUR-LOG |

Date 2006 |

12. Quality standards

The establishment and certification of quality management systems at Bosch Rexroth is done as per DIN EN ISO 9001:2000. It ensures large-scale measures that clearly determine the entire procedures within BR that exceed the usual quality assurance.

Furthermore, Bosch Rexroth has incorporated the ISO/TS 16949, which contains allhitherto existing and published international quality standards and stipulations on aquality management system by the automotive sector. It is based on the ISO9001:2000.

In addition, the quality management system audit VDA 6.1 is used at Bosch Rexroth.

13. Guarantee bond

The contractor guarantees Bosch Rexroth AG to package correctly complying with the minimum requirements described in the manual as well as flawless quality of the packaging material. For possible necessary deviations from these conditions, prior approval by Bosch Rexroth must be given. The contractor is liable to the customerfor all damage arising from defective design of the packaging as well as from non-compliance with the minimum requirements.

29

09_Packaging_Instructions